What are carbon nanotubes? Carbon nanotubes are cutting-edge materials that have unique properties and wide-ranging applications. This guide will explore their properties, types, synthesis methods, and applications.

What Are Carbon Nanotubes?

Carbon nanotubes (CNTs) are cylindrical structures made of carbon atoms. These atoms are arranged in a hexagonal pattern, similar to a honeycomb lattice. The cylindrical molecules can have diameters as small as a few nanometers (nm). Their lengths can range from micrometers to millimeters. CNTs can behave like metals, semiconductors, or insulators. This depends on how their structure is configured. This makes CNTs highly adaptable to various applications.

History of Carbon Nanotubes

The history of carbon nanotubes began in 1991. Japanese scientist Sumio Iijima first discovered them while working at NEC. He used a transmission electron microscope (TEM) to make the discovery. His findings showed that CNTs were unknown before, and their unique properties were still unexplored. This discovery changed the field of nanotechnology.

Before this, carbon nanotubes were only theorized. In the 1950s, scientists like Richard Smalley guessed about cylindrical carbon structures. They thought these structures might exist because carbon forms stable molecular shapes. But it wasn’t until the 1990s that CNTs became widely known. Iijima’s discovery brought CNTs into the scientific world’s focus.

Carbon Nanotubes Structure

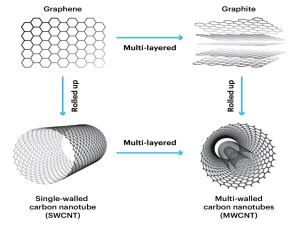

The structure of carbon nanotubes is key to their unique properties. A carbon nanotube is a single sheet of graphene, a layer of carbon atoms arranged in a honeycomb shape. This sheet is rolled into a tube. The bonds between the carbon atoms are strong, giving CNTs their strength and stability.

CNTs have two main dimensions: diameter and length. The diameter ranges from 0.7 to 50 nm. Their lengths vary from a few micrometers to several millimeters. The strong carbon bonds give CNTs great strength. The hollow center increases the surface area. This helps with electrical and thermal conductivity. The structure also makes CNTs flexible. They can bend and stretch without breaking.

Types of Carbon Nanotubes

1. Single-Walled Carbon Nanotubes (SWCNTs)

Single-walled carbon nanotubes (SWCNTs) are made from a single graphene layer. This layer is rolled into a cylindrical shape.

SWCNTs are the simplest form of CNTs. They are often considered the most promising for high-tech applications. Their diameter typically ranges from 0.7 to 2 nm. The length of SWCNTs can extend up to several micrometers. These unique properties make them ideal for a variety of applications.

- Properties:

SWCNTs have unique electrical properties suitable for electronic components like transistors, sensors, and displays. The way the graphene sheet is rolled determines the SWCNT’s behavior.

If rolled in a certain way, the SWCNT exhibits metallic conductivity. When rolled differently, it becomes a semiconductor with specific electronic band gaps.

- Applications:

SWCNTs are incredibly strong and lightweight, making them ideal for the aerospace and automotive industries, where materials must be strong and light. Their high surface area also makes them suitable for energy storage applications. SWCNTs can improve performance in supercapacitors and batteries.

2. Multi-Walled Carbon Nanotubes (MWCNTs)

Multi-walled carbon nanotubes (MWCNTs) are made of several layers of graphene nested inside each other, forming a tube. They usually have 2 to 100 nm diameters and are much thicker than single-walled carbon nanotubes (SWCNTs). The extra layers give MWCNTs more strength and stability. This structure also helps them resist deformation when under stress.

- Properties:

The inner layers of MWCNTs often act like metals, and the outer layers can act like metals or semiconductors. This makes MWCNTs useful for many applications. They are used in advanced materials and conductive films. MWCNTs are also key parts of the electronics industry. Their unique properties help them work in different fields.

- Applications:

MWCNTs help strengthen materials. They are added to polymers and metals, making them more rigid and durable. MWCNTs also improve how well the materials carry electricity and heat, making them light but strong. This is useful in industries like aerospace, automotive, and construction.

Carbon Nanotubes Properties

The properties of carbon nanotubes are remarkable and contribute to their use in a wide range of applications. Here’s a deeper dive into the key properties of CNTs:

1. Strength

Carbon nanotubes are among the strongest materials known to man. Their tensile strength is over 100 times greater than steel’s, yet they are much lighter. This strength comes from the robust and highly stable carbon-carbon bonds within graphene layers. The nanotube structure acts like a reinforced cylinder, able to withstand extreme stress without breaking. CNTs are used to improve the strength of composite materials. They enhance polymers, metals, and other materials effectively.

2. Electrical Conductivity

CNTs have extraordinary electrical conductivity, making them highly useful in electronics. Their structure allows electrons to move freely when the graphene sheet is rolled into a tube, making CNTs excellent conductors of electricity. Depending on the chirality of the graphene sheet, CNTs can behave like metals or semiconductors, making them ideal for high-performance transistors, solar cells, and sensors.

3. Thermal Conductivity

Carbon nanotubes are exceptional heat conductors. Their thermal conductivity exceeds that of most metals. This property makes CNTs ideal for heat management in electronic devices. They are also helpful in aerospace components. CNTs improve the heat resistance of industrial systems, enhancing performance in various applications.

4. Flexibility

Despite their incredible strength, CNTs are also highly flexible. This flexibility allows them to bend and deform without breaking. Combined with their strength, this property is highly beneficial. This makes CNTs ideal for applications like flexible electronics. Traditional materials might crack or fail under stress, but CNTs do not. This makes them a valuable material for innovative, durable, and adaptable technologies.

5. Lightweight

Carbon nanotubes are incredibly light, yet they do not sacrifice strength for weight. This property is essential in applications requiring lightweight materials without compromising structural integrity. For example, CNTs are used in the aerospace industry to create strong, lightweight materials for aircraft and spacecraft components.

How to Manufacture Carbon Nanotubes?

Manufacturing carbon nanotubes requires advanced techniques, and several methods have been developed to produce them efficiently. Some of the most common methods include:

1. Chemical Vapor Deposition (CVD)

The Chemical Vapor Deposition (CVD) method is widely used for synthesizing CNTs. In CVD, gaseous hydrocarbons like methane are introduced into a chamber. A heat source, such as a furnace or plasma, decomposes these hydrocarbons.

The decomposition occurs at high temperatures, producing carbon atoms. These carbon atoms then deposit onto a substrate, typically a metal catalyst. Typical catalysts include iron, nickel, or cobalt. The carbon atoms form nanotubes during this process. CVD allows the production of both SWCNTs and MWCNTs, depending on parameters. This method is highly scalable and suitable for large-scale production. It is one of the most popular methods for commercial CNT production.

2. Arc Discharge Method

The Arc Discharge method creates an electric arc between two graphite electrodes. As the arc passes through the electrodes, it vaporizes the carbon material. The vaporized carbon condenses to form carbon nanotubes. This method is effective for producing both single-walled and multi-walled nanotubes. However, it often makes other carbon structures, such as fullerenes and carbon soot. These byproducts need to be separated from the CNTs. Arc discharge produces high-quality CNTs. However, it is less scalable compared to CVD. It can also be challenging to control the structure of the nanotubes.

3. Laser Ablation

In the Laser Ablation method, a high-powered laser vaporizes a graphite target. The target is placed in a furnace under controlled conditions. The carbon vapor produced is then condensed to form carbon nanotubes. This method is mainly used to produce high-quality SWCNTs. The laser ablation technique requires high temperatures to function correctly. It also needs precise control of the reaction environment. This makes it less suitable for mass production compared to CVD.

Carbon Nanotubes Uses and Applications

Carbon nanotubes have numerous applications across various industries due to their unique properties. Some of the primary uses include:

Electronics and Semiconductors

CNTs have exceptional electrical conductivity and small sizes, making them ideal for transistors, sensors, and other semiconductor devices. Depending on their structure, CNTs can act as metallic conductors or semiconductors. This flexibility makes them highly attractive for miniaturized electronic devices. Traditional materials like silicon may not be suitable due to size limitations. CNTs offer superior performance in such cases, overcoming the challenges posed by conventional materials.

Energy Storage and Batteries

The unique properties of CNTs make them ideal for energy storage devices. Their large surface area and high conductivity are key factors. CNTs improve the capacity and performance of supercapacitors and lithium-ion batteries. They enhance the electrical and thermal properties of these devices. This leads to more efficient energy storage and faster charging times.

Composite Materials

Carbon nanotubes are used to reinforce composite materials. This makes them stronger, lighter, and more durable. CNTs are often added to polymers, metals, and ceramics. They enhance the properties of these materials without significantly increasing their weight. These improved materials are used in the aerospace, automotive, and sports equipment industries. In these industries, performance and strength are critical.

Medical Applications

CNTs are being explored for drug delivery, imaging, and biosensing applications. Their small size allows them to penetrate biological membranes easily. This makes them ideal for targeted drug delivery. CNTs can be functionalized with specific molecules. These molecules help CNTs target cancer cells or disease sites. It also improves the efficacy of treatments. This opens up new possibilities for precise and effective medical therapies.

Conclusion

Carbon nanotubes revolutionized material science with mechanical, electrical, and thermal properties. Since their discovery in the early 1990s, CNTs have had diverse applications. Applications include electronics, energy storage, composite materials, and medicine, with new uses emerging.

CNTs’ potential applications will expand across various industries as manufacturing techniques improve. This expansion will open new opportunities in fields like nanotechnology and space exploration. Continued study of CNTs will lead to advancements in several technological fields. These advancements will impact industries, fostering innovation and progress in many areas.