Carbon nanotubes are one of the greatest inventions of science. They are used in construction, electronics, and medicines. What makes them more popular is their unique properties. They are durable, lightweight, and conductors. However, if you believe all carbon nanotubes are the same, you might be wrong. There are two major types of carbon nanotubes existing. They are categorized into single-walled and multi-walled carbon nanotubes.

Now, you might be wondering how to choose the best one. Well, this choice depends on your preference. Here is the list of differences between SWCNTs and MWCNTs. It also discusses the practical applications, features, and structure. Here we go.

Understanding Carbon Nanotubes

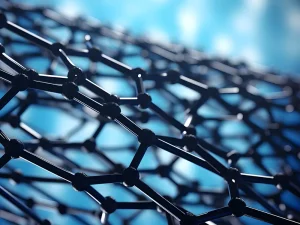

Let’s quickly understand the meaning of carbon nanotubes first. It will make everything clear. After that, you can make real decisions:

In general, there are two main types of carbon nanotubes:

- Single-walled carbon nanotubes (SWCNTs)

- Multi-walled carbon nanotubes (MWCNTs)

What makes the real difference is the structure of both the nanotubes.

A Closeup of Single-Walled Carbon Nanotubes (SWCNTs)

Let’s first start with understanding the meaning of SWCNTs. SWCNTs expand as Single-Walled Carbon Nanotubes. Here are other details:

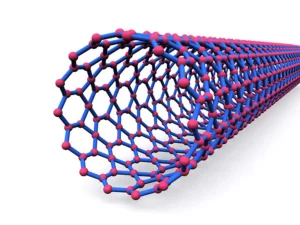

Structure

SWCNT consists of a single layer of graphene rolled into a cylindrical tube. In general, their diameters range between 0.7 to 2 nanometers. Or, in simple words, SWCNT particles have really small sizes.

Properties

Let’s go through the properties of single-walled carbon nanotubes. Here are properties

- Simple and uniform structure

- Lightweight

- High flexibility

- Excellent electrical conductivity

Applications

The unique structure of SWCNT makes them ideal for different high-tech applications. Here are the common uses:

- Electronics: In transistors and sensors

- Medicine: For targeted drug delivery

- Energy: In solar cells and batteries

Limitations

Apart from benefits, there are certain limitations of SWCNT, which include:

- Because of the complex synthesis method, SWCNT is expensive.

- It is still challenging to produce these nanotubes on a large scale.

- It’s complex to produce consistent and pure molecules.

- Mechanically, SWCNT is fragile.

A Closeup of Multi-Walled Carbon Nanotubes (MWCNTs)

Now, let’s understand the meaning of MWCNTs. MWCNTs expand as multi-walled carbon nanotubes. Here is what makes it different from its counterparts.

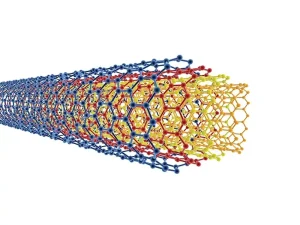

Structure

The real difference between MWCNT and SWCNT is the structure. Multi-walled carbon nanotubes contain multiple graphene layers. These layers are rolled in a concentric manner.

In simple words, MWCNTs are several SWCNTs stacked on one another. The diameter ranges between 10 to 50 nanometers. Thus, they are bigger than their counterparts.

Properties

Now, let’s take a look at the properties of the MWCNT:

- Strong bond

- Rigid structure

- Less Flexible

- Durable

- Cost-effective

- Easy to produce

Applications

Now, let’s understand the applications of MWCNTs. Since these particles are durable and easy to produce, they are used in industries:

- Construction: To bring durability in cement and polymers

- Automotive: To enhance the functions of car components.

- Energy: In capacitors and energy storage devices.

Limitations

- The structure scatters phonons that reduce efficiency.

- The nanotube is prone to defects during synthesis.

- The molecule is heavier, adds to the weight, and reduces flexibility.

- Electrical conductivity is lower compared to SWCNTs.

Key Difference Between Single-walled and Multi-walled Carbon Nanotubes

Let’s now quickly cover the major points of differences between the nanotubes:

Structure and Size

SWCNTs have a simple structure compared to MWCNTs. The latter one is complex and bigger. While SWCNTs have a small diameter of 1nm, MWCNTs’ diameter ranges between 2nm and 100nm.

Mechanical Strength and Durability

Next comes the durability of these carbon nanotube variants. SWCNTs are delicate yet have high strength. Thus, they are prone to damage. In contrast, MWCNTs are rigid and can handle high pressure. They have more mechanical strength, which makes them more powerful.

Electrical Conductivity

Looking for electrical conductivity? Choose SWCNTs for electronics and energy applications. However, MWCNTs provide varied conductivity, with the outer layers acting as semiconductors.

Thermal Conductivity

Thermal conductivity is the ability of metal to allow the passage of heat particles. SWCNTs are better heat conductors than MWCNTs. Their uniform, single-layer structure makes them best for heat conduction. Besides, their thermal conductivity can reach as high as 3500–6000 W/m·K, which is higher than that of MWCNTs.

Production and Cost

If you want to talk about production costs, MWCNTs are affordable and easy to produce. However, because of its structure, SWCNTs are cheaper and can be easily produced.

To make the things more clear, here is a tabular compilation:

| Features | SWCNTs | MWCNTs |

| Structure | Single graphene sheet rolled into a tube | Multiple graphene sheets rolled together |

| Diameter | 0.7–2 nm | 10–50 nm |

| Flexibility | High Flexibility | Low Flexibility |

| Strength | Moderate | High |

| Cost | Expensive | Cost-Effective |

| Applications | Electronics, medicine, and nanotech | Industrial and construction fields |

Which Nanotube Should You Use

Choosing between SWCNTs and MWCNTs totally depends on your needs and requirements:

Choose SWCNTs

Suppose you need high flexibility, precise performance, and better electrical conductivity. Or, in other terms, you can use it for medical and electronics.

Choose MWCNTs

Suppose you need strength, durability, and cost-efficiency. In other words, they are perfect for large-scale industrial use.

Is It Possible To Modify Carbon Nanotubes

One of the most asked questions is whether it is possible to modify carbon nanotubes. When synthesized using certain methods, it is possible to customize carbon nanotubes. You can mix the number of side walls. If you are wondering how it works, here is a quick guide. While manufacturing nanotubes, one can break the outer cells of the molecule. This process allows the addition of molecular complexes to one another, changing the overall property. This simple change can change other properties.

Quick Recap

It is important to understand the differences if you are working on carbon nanotubes. The difference between single-walled and multi-walled carbon nanotubes is greater. Be certain about the features of both types of nanotubes.

SWCNTs are lightweight, flexible, and ideal for advanced technology applications. In contrast, MWCNTs are more durable, thus perfect for industrial and large-scale use. However, both carbon nanotubes play a significant role in shaping modern industries. As technology evolves, their applications will only expand further.