In the search for safer, longer-lasting, and faster-charging lithium batteries, carbon nanotubes (CNTs) are emerging as a prospective material. These rolled sheets of carbon atoms possess unparalleled electrical conductivity, remarkable mechanical strength, and outstanding thermal stability. They are ideal for next-generation battery technology. At Dazhan Nanomaterial, we produce high-purity multi-walled carbon nanotubes (MWCNTs) using scalable and cost-effective CVD techniques. Unlike traditional conductive additives such as carbon black or Super-P, CNT conductive slurry strengthens electrodes on both sides. It creates a rigid, complex network within battery electrodes. This improves charging rates and energy density and decreases material wastage.

Introduction to Carbon Nanotubes (CNTs)

Carbon nanotubes (CNTs) are cylindrical nanostructures made of rolled-up sheets of single-layer carbon atoms (graphene). Among various types, multi-walled carbon nanotubes (MWCNTs) are widely used in battery applications due to their excellent electrical and mechanical properties.

We produce high-purity carbon nanotube powder by CVD method. The purity can reach more than 97.5%. This method can produce multi-walled carbon nanotubes suitable for various industrial applications on a large scale and at low cost.

Key characteristics of our CNTs include:

- High purity and stable quality

- Large specific surface area

- Outstanding electrical conductivity

- Exceptional mechanical strength

These properties make CNTs an ideal base material for conductive slurries in lithium-ion battery electrodes, where superior conductivity, dispersion, and structural integrity are required.

Conductive Mechanism of Carbon Nanotubes

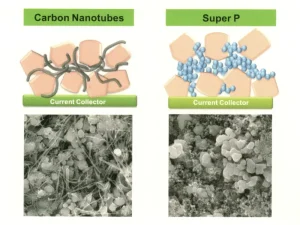

1. CNTs have a larger aspect ratio than granular Super-P. They easily form a conductive network on the surface of the active material, improve the bonding strength between the active material and the collector, and reduce the amount of conductive agent.

2. CNTs have a certain lithium insertion capacity as a negative electrode conductive agent. This can form a synergistic effect with the negative electrode active material to improve the specific capacity of the composite electrode.

3. Carbon nanotubes have good thermal conductivity. This is conducive to heat dissipation during battery charging and discharging. Compared with additives such as carbon black, carbon nanotubes can improve the battery’s safety and high- and low-temperature performance.

4. Carbon nanotubes have good strength and flexibility. They can prevent the battery from breaking and entangle the active material particles when the battery is running or the environment changes. This avoids separation between particles during the cycle and improves the cycle performance of the battery.

Advantages of CNTs in Lithium Batteries

- CNT conductive paste helps increase the percentage of active materials, leading to higher energy density. It reduces the amount of conductive agents and binders needed in the electrode.

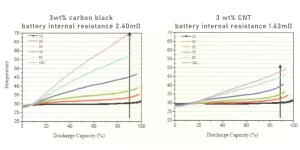

- CNTs enhance active material utilization, allowing batteries to deliver higher specific capacity. They significantly lower internal resistance, improving both charging and discharging performance at high rates.

- CNT paste helps reduce surface temperature during fast charging and discharging.

- It improves battery performance in low-temperature environments by maintaining conductivity.

- CNTs improve electrolyte absorption, enhancing the battery’s cycle life and stability.

CNT conductive paste can be used in the following batteries:

- High energy density

- High rate

- Long cycle life

- Usable in ultra-high and ultra-low temperature environments

Advantages of Our CNT Conductive Slurry

1. Improves Cathode Electrode Processing – For Ternary Systems

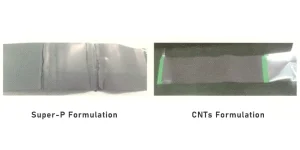

Our CNT slurry replaces traditional Super-P and makes electrode processing more stable. It prevents sheet breakage during rolling and stops powder from falling off the electrode. This improvement increases the battery’s production yield.

Compared to Super-P, our CNT formula allows a higher solid content and reduces the use of NMP solvent. This helps lower battery manufacturing costs.

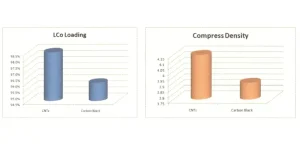

2. Increases Energy Density – For Lithium Cobalt Oxide (LCO) Batteries

Our CNT slurry increases the active material loading in the cathode (98.5% vs 96%). It also improves the cathode compress density (4.15 g·cm⁻³ vs 3.9 g·cm⁻³). These changes help raise the energy density of the battery.

3. Improves Battery Safety – For LFP Batteries

At the same amount of conductive agent, batteries using CNT show lower surface temperatures during 10C discharge (49°C vs 68°C).

Better conductivity leads to lower heat generation and a longer battery lifespan. It also improves rate performance and overall battery safety.

4. Enhances High-Rate Performance – For LFP Batteries

| Item | Battery Type | 1C | 2C | 3C | 5C | 8C |

|---|---|---|---|---|---|---|

| Constant Current Charging | 3% CNT | 98% | 94% | 93% | 92% | 88% |

| Electrical Efficiency | 3% Carbon Black | 92% | 82% | 79% | 73% | 12% |

CNT slurry improves electron transport within the electrode. This allows the battery to maintain strong performance even under fast charge and discharge conditions.

5. Improves High-Temperature Cycle Life – For Ternary Soft-Pack Cells

| Conductive Agent | 1% CNT | 3% Carbon Black | ||

|---|---|---|---|---|

| Battery AC Impedance (mΩ) | 44 | 46 | ||

| Cathode Compaction Density (g/cm³) | 3.7 | 3.7 | ||

| Rate Discharge | 1C/0.2C | 91.50% | 1C/0.2C | 92.40% |

| 2C/0.2C | 79.30% | 2C/0.2C | 79.40% | |

| 3C/0.2C | 63.80% | 3C/0.2C | 64.80% | |

A battery using only 1% CNT (one-third the usual amount of conductive agent) shows better energy density and improved cycling at 45°C.

Although CNTs are similar in price to Super-P, their required dosage is much lower. This helps reduce the total cost of battery production.