Carbon is one of nature’s most versatile building blocks. Strong, lightweight, and incredibly adaptable, carbon-based materials power countless products we use daily. From tires to touchscreens, carbon helps build our modern world. The traditional carbon black that industries have relied on for decades. The new-gen carbon nanotubes that reinvent what’s possible in material science. Although these two options offer unique advantages, carbon nanotubes deliver benefits that have manufacturers, engineers, and scientists taking notice. Carbon nanotubes VS carbon black, which is better for industrial use? Let’s break down the differences and see why the dark horse-like variant, carbon nanotubes, often wins this match-up.

What Are Carbon Blacks?

Carbon black has been around for over 100 years. It is mainly used to strengthen rubber products and as a pigment in inks and coatings. This material consists of tiny, round carbon particles that come from burning oil products.

Industries have used carbon black for decades because it:

- Provides affordable black coloring for many products

- Offers some electrical conductivity to reduce static buildup

- Protects plastics and coatings from UV damage

- Adds strength to rubber tires and similar products.

Carbon black works well for these basic uses, but today’s tech needs carbon materials that can do more. This need has led to the rise of carbon nanotubes, which work better in almost every way.

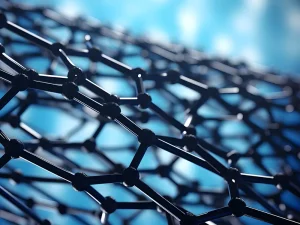

What Are Carbon Nanotubes?

Carbon nanotubes (CNTs) represent a tremendous breakthrough in how we use carbon today. These tiny tubes have walls made from carbon sheets just one atom thick (called graphene) rolled into cylinders. This creates materials with amazing properties.

CNTs are available in two main varieties:

- Single-walled carbon nanotubes (SWCNTs) – made of a single layer of carbon atoms.

- Multi-walled carbon nanotubes (MWCNTs) – comprising multiple tubes nested inside each other.

Key Advantages of Carbon Nanotubes Over Carbon Black

1. Superior Strength

Carbon nanotubes (CNTs) demonstrate exceptional mechanical strength that carbon black cannot match.

CNTs are among the strongest materials ever found. They are about 100 times stronger than steel while being six times lighter. This makes carbon nanotubes perfect for uses where both strength and lightness matter.

In addition, CNTs are very flexible, allowing them to bend without breaking and spring back to their original shape afterward. This mix of strength and flex encourages the development of new materials that would be impossible with carbon black alone.

2. Better Electrical Conductivity

While carbon black conducts some electricity, carbon nanotubes conduct up to 1,000 times better. This means you can use less material and get better electrical results.

Even more impressively, carbon nanotubes can act as semiconductors or metals based on their structure, offering options that carbon black cannot provide. This flexibility has opened new possibilities in electronics, batteries, and sensor technologies.

3. Excellent Heat Transfer

Heat control is a big challenge for many modern devices. Fortunately, carbon nanotubes excel in this aspect. They have heat conductivity values far beyond what carbon black offers. This ability makes CNTs valuable for materials that need to transfer or distribute heat effectively.

4. Mixes Better with Other Materials

Carbon nanotubes blend more evenly throughout base materials when properly prepared. This even mixing creates final products with more consistent properties throughout.

The even spread also means you can get the results you want while using less material.

Many customers ask us: “Why should we switch from carbon black to carbon nanotubes?” As a leading carbon nanotubes manufacturer, our answer is clear. While both are carbon-based, CNTs deliver unmatched advantages in conductivity, strength, and versatility. Our manufacturing process ensures top quality and performance in all our CNT products.

Applications: Carbon Nanotubes VS Carbon Black

1. Better Batteries and Energy Storage

In batteries and supercapacitors, carbon nanotubes outperform carbon black in several ways. First, CNTs create a network within battery parts that lets electricity flow freely. This network comes from its tube shape, unlike the round bits of carbon black.

With CNTs, batteries can charge up to 60-70% faster and store more energy. This is a result of the electrical conductivity and large surface area (up to 1,300 square meters per gram) of CNTs.

In real-world testing, batteries with carbon nanotubes keep 20-30% more capacity after 500 charges compared to carbon blacks. This stability comes from CNTs’ ability to tolerate the expansion and contraction that happens during charging and discharging. Some products that benefit from this trait are electric vehicles and portable electronics.

2. Stronger Composite Materials

Traditionally, carbon blacks were used to strengthen rubber and plastics. Now, however, CNTs provide better reinforcement with just a fraction of the material.

Adding just 0.5% of carbon nanotubes by weight can increase the strength of some plastics by 30-40%. To achieve similar results with carbon black, you’ll need 5-10% more material.

Stronger composites have many real-life benefits. For example, aerospace components made with CNT-reinforced composites are up to 25% lighter. This is in comparison with traditional materials.

Cars also benefit by gaining better impact resistance and longer service life. Even sports gear like tennis rackets and golf clubs benefit from CNTs’ vibration control and strength-to-weight ratio.

3. Advanced Electronics and Sonars

CNTs form semiconductor components with better electron mobility than even silicon. Hence, they provide faster, more efficient electronic units within devices.

When used in sensors, carbon nanotubes improve sensitivity. Gas sensors made with CNTs are 50-100 times more sensitive than carbon black sensors. This is due to their unique structure, where small changes cause measurable electrical shifts.

Medical sensors using carbon nanotubes can detect disease biomarkers earlier.

Environmental sensors can monitor pollution more accurately.

Industrial sensors can provide more precise quality control.

Each of these applications represents a significant advancement over what we know is possible with carbon black.

Quality Matters: Finding the Right Carbon Nanotube Supplier

While carbon nanotubes offer clear benefits, getting these advantages requires high-quality materials from skilled makers.

At Dazhan, we specialize in making premium carbon nanotubes with consistent properties and reliable performance. Our manufacturing expertise ensures that customers receive materials that consistently deliver the above-described advantages.

Our carbon nanotubes go through careful quality testing to check their structure, purity, and performance. This careful attention ensures your products get the full benefit of CNT technology. If you have any needs, please contact us immediately