Carbon-based materials have transformed the world with their incredible properties. Carbon fibers and carbon nanotubes are the most widely used among those materials. Each of them has unique properties, strengths, and weaknesses. Although both share the same origin, what sets them apart, and which is truly superior? This is the burning question when choosing between these materials. Let’s find this answer in this article by briefly comparing carbon fiber VS carbon nanotubes.

What is Carbon Fiber and Carbon Nanotubes

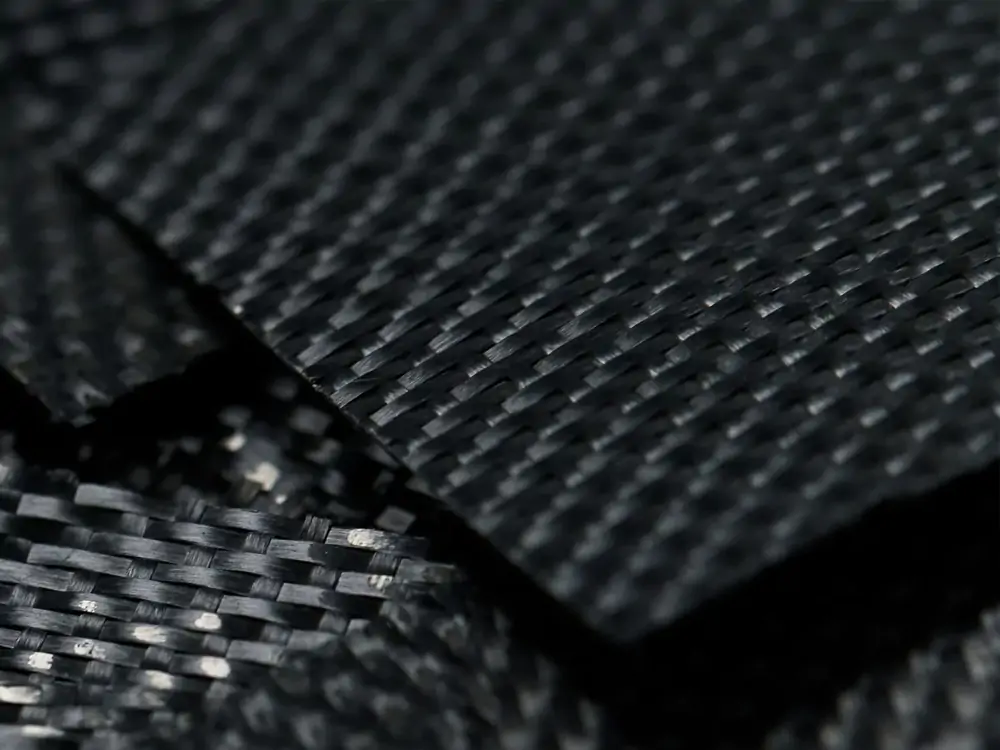

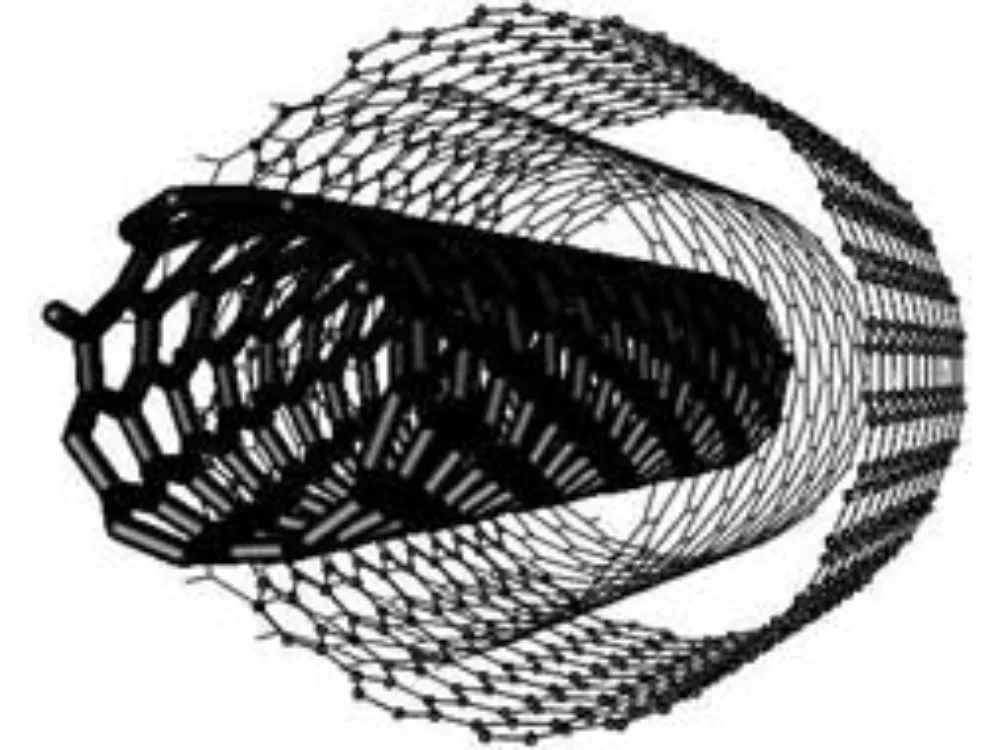

A material made of delicate carbon atom filaments is called carbon fiber. The carbon atoms in filaments have hexagonal geometry, giving a fiber crystalline structure. On the flip side, tube-like structures made of entirely carbon atoms are called carbon nanotubes. Commonly, nanotubes are also known as nanomaterials.

We conclude that both materials use the same carbon atoms in their composition. But how are they made? Carbon fibers are formed initially from polyacrylonitrile, a polymer containing some non-carbon atoms. All those atoms are removed by heating them at a high temperature. After their removal, the process of Graphitization begins.

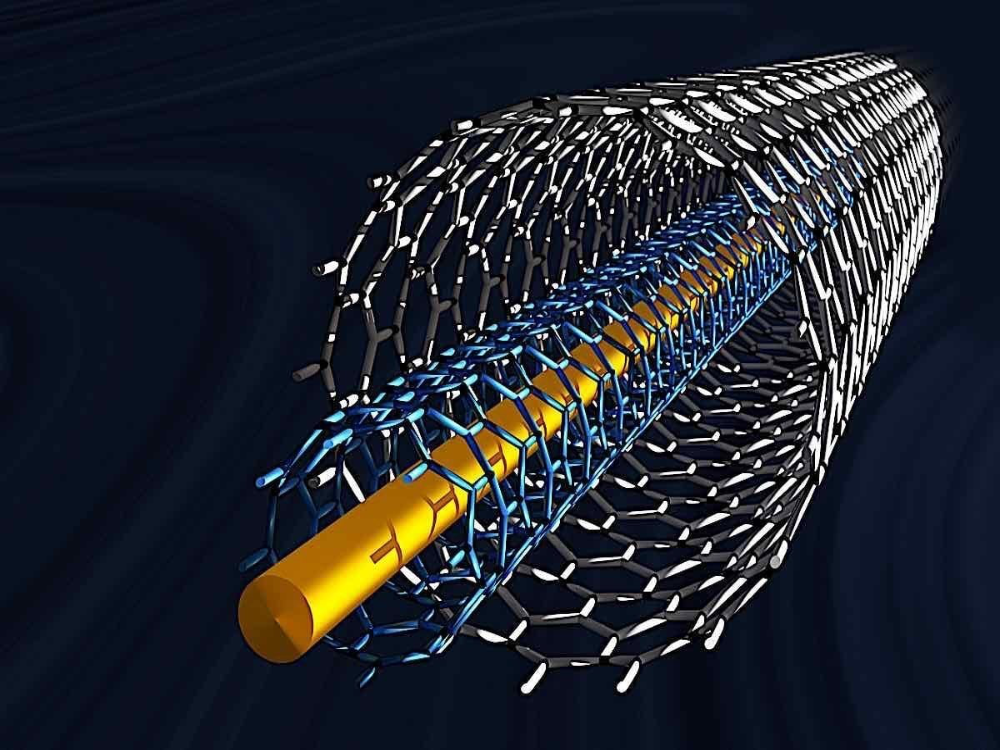

This process adds carbon atoms to the polymer in a controlled manner. As a result, a unique fiber with a uniform structure is obtained. These carbon fibers are stiff, rigid, and durable. On the reverse side, carbon nanotubes are made using the Chemical Vapor Deposition( CVD) process. In this process, high atomic hydrocarbons are heated and decomposed.

On heating, carbon atoms deposit layer by layer on the surface and are rolled into tubes. However, additional by-products leave the surface by vaporization. The carbon atoms are also arranged in a hexagonal pattern in carbon nanotubes. Thus, they also have uniformity in their structure. But the size of nanotubes is a thousand times that of human hair.

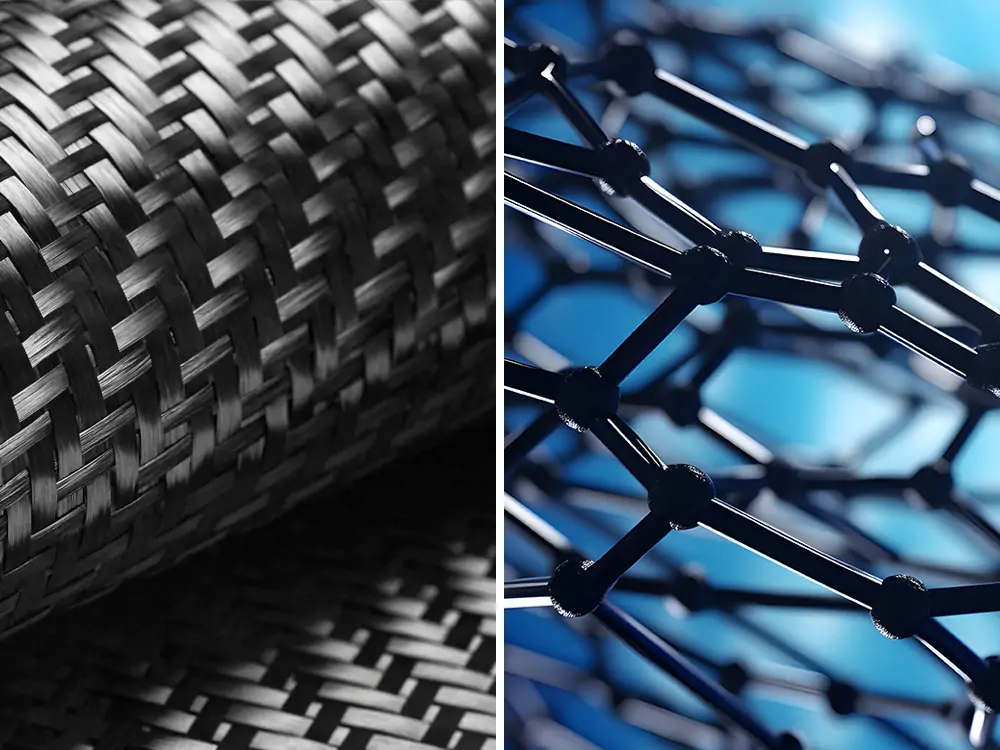

Carbon Fiber VS Carbon Nanotubes: Key Differences

The basic overview has given you enough understanding of both materials. Both are undoubtedly made of carbon, but several other aspects set them apart. The section below will share some key differences that eliminate confusion. Let’s dive in!

1- Strength and Durability

Strength and durability heavily rely on the arrangement of atoms in a material. Carbon fiber and carbon nanotubes differ in this regard. For example, carbon fiber has a crystalline structure that enhances its rigidity. This means it can easily withstand the force of tension. However, due to its uniform structure, it lacks flexibility.

Thus, carbon fiber cannot withstand sudden impacts and becomes brittle. On the other hand, carbon nanotubes are the strongest materials ever known. All the carbon atoms are sp² hybridized, which makes the chemical bond unbreakable. Moreover, the tenfold higher tensile strength makes them durable and ductile for any heavy force.

2- Weight and Handling

In terms of weight and handling, carbon nanotubes are the clear winner. The reason lies in the cylindrical and tube-like structure. The hollow shape of this material makes them almost weightless at the atomic level. Moreover, the 1.3–1.4 g/cm³ density further decreases its weight. So, due to such extremely low weight, handling nanotubes is also easy.

For example, they are easy to fabricate in complex shapes without breaking. On the reverse side, carbon fibers have a slightly higher weight. Their density is almost between 1.6 and 2.2 g/cm³. The reason is the layer formation of threads. Moreover, the less flexibility also makes it challenging to handle. For instance, carbon fiber is hard to shape and cut.

3- Flexibility and Elasticity

Carbon fiber is less flexible. But what is the reason for this lack of flexibility? Actually, these fibers have a directional alignment of carbon atoms. The strong covalent bond makes them stiffer and more rigid. So when you apply a heavy force, they show brittleness and break quickly. In simple words, carbon fibers have limited tensile strength.

Beyond this limit, they break. On the flip side, carbon nanotubes have excellent flexibility and elasticity. The reason lies in cylindrical and tube-like shape. This shape absorbs the energy of force applied and releases it quickly without deformation. Most nanotubes are so flexible that you can stretch them up to 20% of their original length without breaking.

4-Electrical and Thermal conductivity

Electrical and thermal conductivity are the two main differentiating factors. If we debate carbon fiber, it is a bad conductor of heat and electricity. WHY? The reason lies in the compact packing of atoms. These tightly packed atoms do not have free electrons that can conduct heat and current. Moreover, the presence of a matrix between threads also disturbs the flow.

On the other hand, carbon nanotubes are good conductors of heat and current. The main reason is their cylindrical shape, which does not hinder free electrons. These free electrons can easily carry heat and current from one end to another. Their higher conductive nature makes them even better than copper.

5- Applications

Due to the differences in many aspects, the application of both materials also differs. Let’s first take a look at the typical applications of carbon fiber:

- Carbon fibers are used in satellite structures due to thermal resistance.

- They are used in support cars and motorcycles to enhance their speed.

- These fibers are transparent to X-rays. So found in x-ray tables and images.

- Due to their lightweight, they are used in earthquake-resistant buildings.

Now, let’s discuss some typical uses of carbon nanotubes.

- They are used in touchscreens and display systems due to conductivity.

- These nanotubes are most commonly used in solar panels and batteries to enhance energy efficiency.

- Medical industries use them in cancer treatment and disease detection.

- They are also used in innovative fabrics that monitor temperature changes.

6- Cost and Affordability

Both materials have significant costs due to the use of advanced technology. However, carbon fibers are more cost-friendly than carbon nanotubes. WHY? The first reason is its straightforward manufacturing process. The raw materials are readily available and less costly. Moreover, they have a higher mass production on large scales, reducing the cost.

On the other hand, carbon nanotubes are extremely expensive. Hydrocarbons, used as raw materials, are costly and difficult to handle. So, using special techniques (CVD) for their manufacturing increases the cost. Additionally, they have low yields in production. It means that a small portion of raw material is converted into nanotubes while a large portion is wasted.

Choosing Between Carbon Fiber and Carbon Nanotubes

As both materials possess unique properties, it becomes very challenging to choose the right one. Are you facing the same confusion? Worry not! This section will discuss some considerations that will help you choose a reliable material for your project.

- First, understand the nature of your project. If your project demands structural strength, go for carbon fibers. However, if flexibility is your primary concern, you should choose carbon nanotubes.

- Although both are lightweight materials, a slight difference still exists. Carbon nanotubes are reliable if you prefer a material known as almost weightless. For more rigidity and density, you should choose carbon fibers.

- Conductance is another factor you should consider before making your selection. Carbon fiber is a good choice if your project involves an insulator material. However, for better heat and current conductance, go with carbon nanotubes.

- Lastly, make a final decision after knowing their prices. Carbon nanotubes may shock your wallet with their higher prices. They are suitable if you want to perform research. However, carbon fiber is slightly cost-effective. They have good production yield, which is a benefit for large-scale projects.

Conclusion

Carbon fibers and carbon nanotubes are two significant carbon-based materials. Because they share the same origin, many people consider them alike. But this is a misconception. This article has discussed several factors that differentiate these materials. For example, nanotubes are more flexible and lightweight. They are also durable, strong, and easy to handle.

Conversely, carbon fibers are also strong but less flexible, making them brittle in a heavy force. Moreover, they are slightly heavier than nanotubes. So, their higher density is used where structural integrity is a significant concern. The readily available raw materials and high production yield make them more cost-effective.