Silicon-based negative electrodes provide high capacity and fast charging capabilities for lithium-ion batteries. So, these batteries are ideal for electric vehicles and energy storage systems. However, they still face limitations such as poor conductivity and significant volume expansion. Moreover, their life cycle is shorter, which is another drawback. The single-walled carbon nanotubes (SWCNT) are the best solution to these challenges. Why? Because they have remarkable conductivity, mechanical strength, and reasonable control over expansion. This article analyzes the problems with silicon-based negative electrodes. It also discusses the benefits of SWCNTs and their promise for future battery tech, like solid-state batteries.

Silicon-Based Negative Electrodes Defects

Silicon-based negative electrodes have the advantage of high specific capacity. Moreover, they have excellent fast charging performance. Despite these benefits, they also have certain defects:

![]()

1- Poor Conductivity

The conductivity of silicon-based negative electrodes is very poor. It is worse than that of traditional graphite negative electrodes. The reason is that silicon is a semiconductor material. Its conductivity is poor, affecting the transmission speed of lithium ions and electrons. Silicon has poor contact with conductive agents and negative electrode binders. This also leads to poor overall conductivity of the electrode.

2- High Volume Expansion Rate

Silicon-based negative electrodes expand and contract a lot during charging and discharging. This happens because of their material properties. Its maximum volume expansion rate can be as high as 300%. It is much higher than the 10-12% of graphite negative electrodes. Massive volume expansion will bring a series of problems. Therefore, the application of silicon-based negative electrodes has strong requirements. They need high safety and stability in battery structure and materials.

3- Low Cycle Life

The cycle life of silicon-based negative electrodes is 300-500 times. It is much lower than the more than 1,500 times of graphite negative electrodes. This is due to the high volume expansion rate of silicon-based negative electrodes. The significant expansion during charging and discharging can pose serious issues.

It can break the active particles into powder. This makes the surface SEI film unstable and causes it to grow. As a result, the electrode structure can collapse. This causes the electrochemical performance of the silicon negative electrode to decay rapidly. As a result, the overall cycle life of the battery is affected to a large extent.

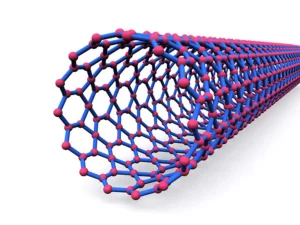

Carbon Nanotubes: The Most Suitable Conductive Agent for Silicon-Based Negative Electrodes

Silicon-based negative electrodes have the defects mentioned above. So, high-performance conductive agents must be added to improve their conductivity. These agents will compensate for their defects and weaknesses. They can better play the performance advantages of high specific capacity and high rate. Carbon nanotubes are the most suitable conductive agent for silicon-based negative electrodes. Carbon nanotubes (especially single-walled carbon nanotubes) are the most suitable conductive agent. They have the following advantages:

1- Excellent Conductivity

Its one-dimensional structure makes it easier to build an effective conductive network. This can make up for the poor conductivity of silicon-based negative electrodes.

2- High Elasticity and Strong Mechanical Properties

SWCNTs have better elasticity (3-10 times that of multi-walled carbon nanotubes. This can make the structure of silicon-based negative electrode materials more stable. It won’t break easily when external forces act on it.

3- Large Specific Surface Area and Excellent Hollow Structure

Carbon nanotubes are the best material for controlling silicon electrode expansion. This can alleviate the stress of the volume change of negative electrodes during charging and discharging. So this reduces material collapse and improves cycle life.

4- Improve Rate Characteristics, High and Low-Temperature Performance

Carbon nanotubes help ions and electrons move faster inside the battery. This results in the fast charging of batteries. Moreover, this material makes the battery withstand high temperatures. Under high temperatures, the battery will support fast charging. This makes them suitable for high-end devices that require rapid charging.

Application of Carbon Nanotube Conductive Agent in Solid-State Batteries

New batteries, especially solid-state batteries, will drive the demand for silicon-based negative electrodes. This will drive the demand for carbon nanotube conductive agents. Solid-state batteries are globally recognized as the next generation of lithium batteries. They have excellent development prospects. They are just starting to industrialize and have caught much market attention.

Solid-state batteries’ solid electrolyte has high ionic and low electronic conductivity. Current research and development systems of solid-state batteries demand carbon nanotube products. Solid-state batteries use more carbon nanotube agents than liquid lithium ones. The application of carbon nanotube conductive agents improves their conductivity and structural stability. They can also extend the cycle life of batteries and increase energy density. These all provide essential support for solid-state battery technology development.

The aspect ratio and carbon purity of carbon nanotubes affect conductivity. They directly determine the product performance of carbon nanotubes. The following parameters increase the conductivity of carbon nanotubes:

- Longer length

- Thinner diameter

- Higher aspect ratio

- Greater carbon purity

Single-walled VS Multi-walled Carbon Nanotubes

| Parameter | Single-Walled Carbon Nanotubes. | Multi-Walled Carbon Nanotubes. |

| Typical Diameter | 1–2 nm | 7–100 nm |

| Typical Length | Up to 1 µm | Up to 1 mm |

| Aspect Ratio | Up to 10,000 | 50–4,000 |

| Elastic Modulus | 1,000–3,000 GPa | 300–1,000 GPa |

| Tensile Strength | 50–100 GPa | 10–50 GPa |

| Thermal Conductivity at 300K | 3,000–6,000 W/(m·K) | 2,000–3,000 W/(m·K) |

SWCNTs have a more significant effect on improving battery performance. They are more suitable for silicon-based negative electrodes.

Currently, the carbon nanotube products on the market are multi-walled carbon nanotubes. The market share accounts for about 80%. Single-walled carbon nanotubes have a single-wall structure. They have a smaller diameter and a larger aspect ratio. So, their physical and chemical properties are better. They conduct electricity better. Their efficiency is 10 times higher than that of multi-walled carbon nanotubes. They also have excellent performance in tensile strength, toughness, and elasticity. The amount of addition is also less.

Single-Walled Carbon Nanotubes Properties

SWCNT can be used in the positive and negative electrodes of lithium batteries. It significantly improves the energy density and rate performance. Moreover, the cycle life and overall safety of the battery also improve. It is more suitable for silicon-based negative electrode materials.

| Advantage | Description |

| Excellent safety performance | At high-temperature multi-week cycles at 45°C, the internal resistance growth of the soft-pack battery with SWCNTs is much lower. This is in comparison to the battery with other conductive agents. This indicates that the battery has a lower risk of fire. |

| Improved Electrode Adhesion | The single-walled carbon nanotube network connects the negative electrode material particles together. This increases the connection strength between the particles. This feature is particularly important for silicon-based negative electrodes. Why? Because they are easy to pulverize and fall off. |

| Simple structure & Stable chemical properties | In multi-walled carbon nanotubes, the gaps between layers easily become trap centers. These centers capture various defects. Single-walled carbon nanotubes have a straightforward structure. They are uniform, have few defects, and show stable chemical properties. |

| Small addition amount & Excellent conductivity | Single-walled carbon nanotubes have a large aspect ratio. They can form a three-dimensional conductive network at extremely low addition amounts. Single-walled carbon nanotubes consist of one layer of carbon atoms. They can exhibit metal or semiconductor properties depending on their spiral structure. Its current density can be more than 1,000 times higher than that of metals such as copper. |

| Good elasticity & High mechanical strength | Single-walled carbon nanotubes have greater flexibility. So they can bend, twist, or kink better. Its elastic modulus and tensile strength are significantly better than multi-walled carbon nanotubes. |

| Good thermal conductivity | The thermal conductivity per unit mass of SWCNTs is higher than that of MWCNTs. At the same time, both can withstand high temperatures above 750°C. |

Conclusion

Silicon-based negative electrodes have promising applications. They are excellent options for the next generations of lithium batteries. However, issues with conductivity, volumetric change, and cycle life present challenges. SWCNTs improve these shortcomings by increasing conductivity and maintaining a stable structure. Moreover, they also enhance the prolonging of the battery’s life. With new technologies like solid-state batteries, the demand for SWCNTs will increase. This will lead to innovation that can transform energy storage systems.