Everything You Need To Know About Multi-Walled Carbon Nanotubes

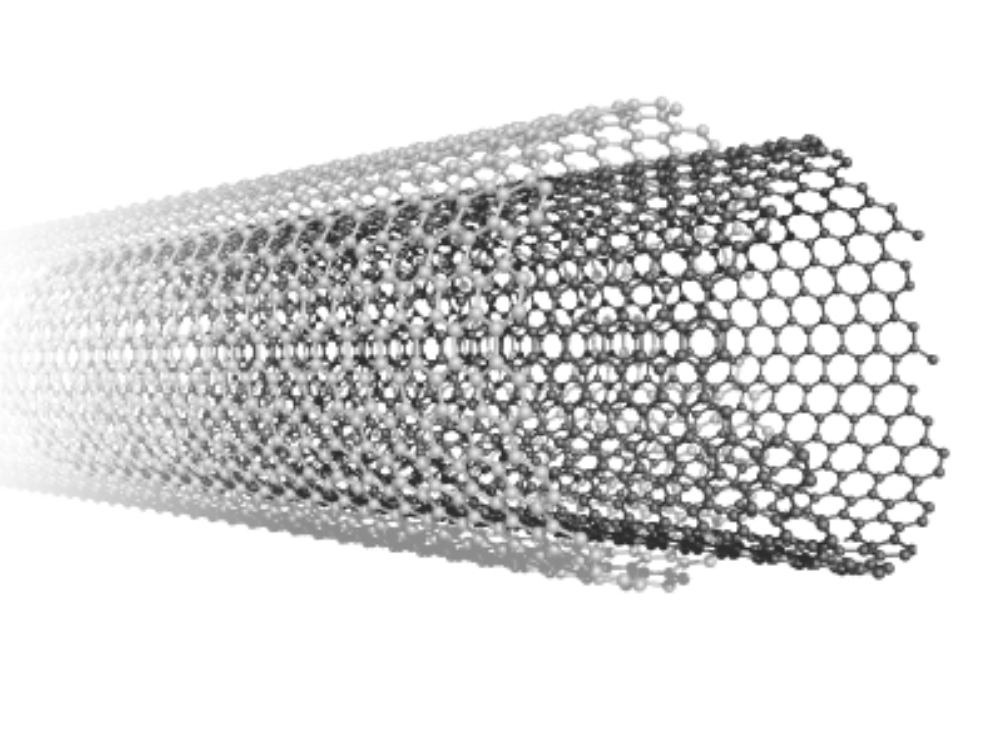

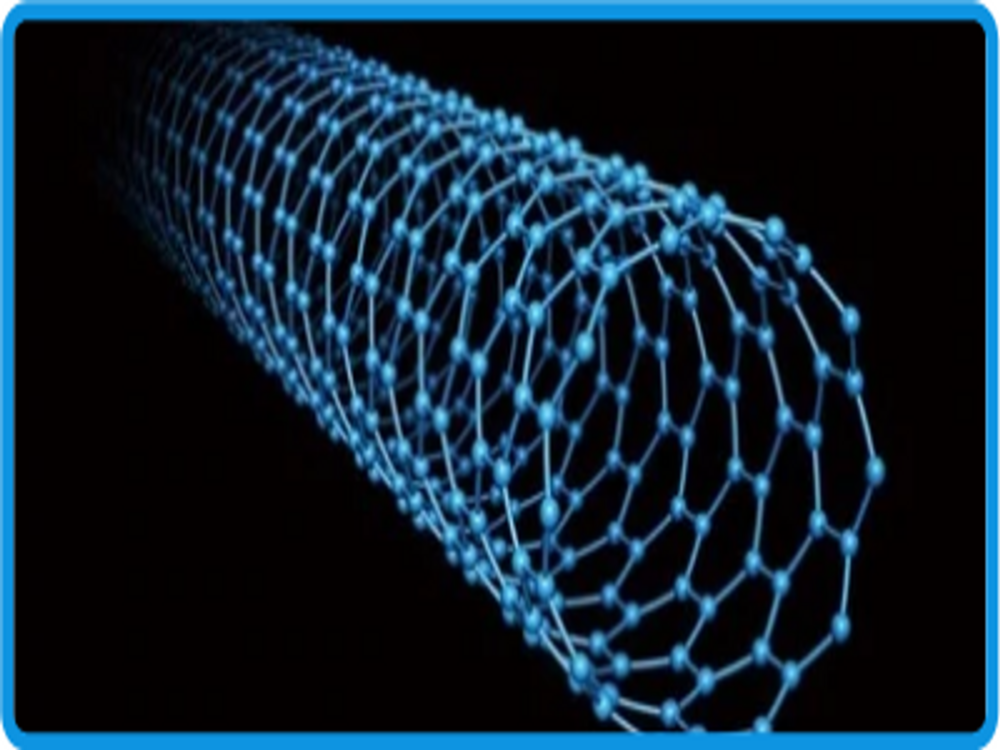

Carbon nanotubes (CNTs) are a type of nanostructures composed of carbon atoms. They are characterized by a tube-like shape, extraordinary thermal conductivity, and an incredibly high mechanical tensile strength. Carbon nanotubes come in two primary forms: single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs). These nanostructures have garnered significant attention in the field of nanotechnology due to their unique properties and applications.

This article walks you through everything you need to know about multi-walled carbon nanotubes. Read on to learn everything from the production of multi-walled carbon nanotubes to properties and safety concerns associated with these carbon nanotubes.

Understanding Multi-Walled Carbon Nanotubes

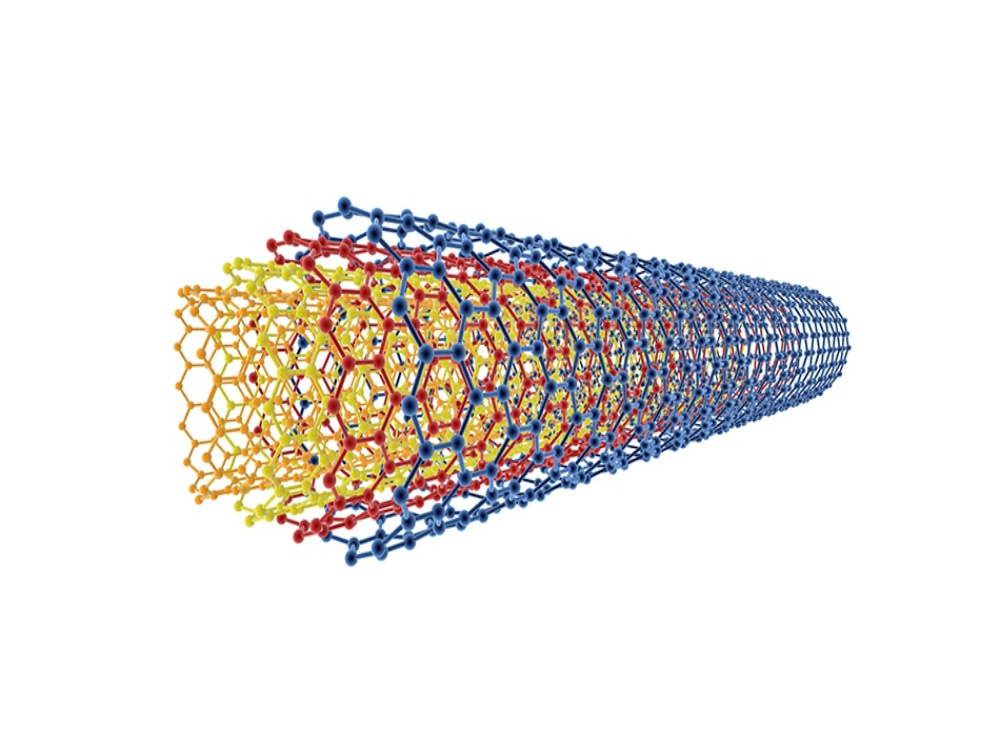

As the name suggests, multi-walled carbon nanotubes comprise multiple concentric layers of carbon nanotubes, like a series of nested tubes within one another. They usually have larger diameters, ranging from 2 to 100 nanometers or more, depending on the number of walls.

Single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs) both belong to the carbon nanotube family but differ in their structure. SWCNTs consist of a single layer of carbon atoms rolled into a cylindrical tube, while MWCNTs have multiple concentric layers.

SWCNTs boast excellent electronic properties due to their one-layer structure. MWCNTs, on the other hand, are often preferred for applications where mechanical strength is essential, like reinforcing materials.

The composition of carbon nanotube multi-walled is almost entirely carbon, with a purity exceeding 95%. This pure carbon composition, along with their unique layered structure, imparts exceptional mechanical, thermal, and electrical properties to these nanotubes.

Overview of the Various Methods Used To Synthesize MWCNTs

There are several methods used to synthesize MWCNTs, each with its own unique advantages and drawbacks. Some of the primary techniques include:

- Chemical Vapor Deposition (CVD): In this method, a carbon-containing gas is decomposed on a catalyst surface at high temperatures. CVD allows for precise control over the growth of MWCNTs. This method is widely used for producing high-quality carbon nanotube multi walled.

- Arc Discharge: Arc discharge involves creating an electric arc between two graphite electrodes in a chamber filled with an inert gas. MWCNTs are produced in the soot generated during the arc discharge. This method can yield MWCNTs with high purity.

- Laser Ablation: High-energy lasers are used to ablate a carbon target, thereby producing MWCNTs in the process. Laser ablation offers good control over the nanotube properties and is particularly useful for research purposes.

- Chemical Synthesis: Various chemical methods, such as the catalytic decomposition of hydrocarbons, can be used to produce MWCNTs. These methods are suitable for large-scale production.

Challenges and Advancements in MWCNT Production

The production of high-quality MWCNTs has encountered several challenges, including:

- Quality Control: Ensuring consistent properties and structural characteristics of MWCNTs in large-scale production has been a challenge. Variability can affect the performance of multi walled carbon nanotube in applications.

- Scalability: Many synthesis methods have limitations when it comes to scaling up production to meet industrial demands.

- Environmental Impact: The environmental footprint of some production methods, particularly those involving toxic chemicals, has been a concern.

Thankfully, advancements have been made in addressing these challenges. Researchers are continuously improving production techniques to enhance the quality and consistency of MWCNTs. Sustainable and green synthesis methods are also being developed to reduce environmental impact.

Role of Catalysts in the Synthesis Process

Catalysts play an important role in the growth of multi-walled carbon nanotubes, especially in methods like CVD. They facilitate the decomposition of carbon-containing gases and the formation of carbon nanotubes. The common catalysts used in the synthesis process include transition metals like iron, nickel, and cobalt.

These catalysts act as sites for carbon atoms to arrange themselves into tubular structures, forming the nanotubes. Keep in mind that the choice of catalyst can significantly influence the properties of the resulting MWCNTs. In recent research, there’s a focus on developing more efficient catalysts.

Properties and Characteristics of Multi-Walled Carbon Nanotubes

Multi walled carbon nanotubes boast a combination of properties that make them versatile and valuable in a wide range of applications. Let’s look at the properties and characteristics of carbon nanotube multi walled.

- Multiple Walls

As the name suggests, multi-walled carbon nanotubes consist of multiple concentric layers of graphene rolled up into a cylindrical structure. These multiple walls provide them with a higher surface area, which can be advantageous for various applications. This is one of the key defining features of carbon nanotubes multi walled.

- Excellent Thermal Conductivity

Speaking of thermal conductivity, multi-walled carbon nanotubes perform really well. These nanotubes are thermally stable to greater than 600 °C. This property makes them ideal for use in materials and composites where efficient heat dissipation is crucial. They can serve as effective thermal management components in electronic devices and even find applications in enhancing the efficiency of heat exchangers.

- Enhanced Mechanical Strength

Defect-free multi-walled carbon nanotubes boast impressive mechanical strength. The multiple walls of these nanotubes reinforce their structure, making them incredibly robust. This is why they commonly find applications in reinforcing materials, such as polymers or ceramics.

- Chemically Stable

Since they are an allotrope of sp2 hybridized carbon, multi-walled carbon nanotubes are known for their chemical stability. They can withstand exposure to harsh chemicals and maintain their structural integrity. This stability ensures that they can be used in a variety of challenging conditions without significant degradation.

- Better Electrical Conductivity

In addition to their chemical stability, multi-walled carbon nanotubes boast excellent electrical conductivity. This property makes them valuable components in the development of advanced electronics, sensors, and even conductive coatings.

- High Aspect Ratio

In terms of aspect ratio, multi-walled carbon nanotubes outperform many other carbon-based materials. The aspect ratio of these carbon nanotubes, which is the ratio of their length to diameter, is notably high. For example, multi walled carbon nanotubes with diameters ranging from 7 to 100 nm have an aspect ratio between 50 and 4000. This is why they are beneficial in applications where a high surface area is needed.

The Impact of Different Synthesis Methods On The Properties Of MWCNTs

The choice of synthesis method for multi-walled carbon nanotubes has a significant impact on their properties. Here’s how different methods influence the characteristics of these nanotubes:

- Diameter and Wall Number

The most noticeable impact is on the diameter and the number of walls in MWCNTs. Methods like chemical vapor deposition yield narrower nanotubes with fewer walls. Techniques like arc discharge and laser ablation often produce wider MWCNTs with more walls. This affects their mechanical, electrical, and thermal properties.

- Purity and Structural Defects

The level of purity and structural defects can vary between synthesis methods. For instance, CVD methods tend to produce purer MWCNTs with fewer defects. In contrast, arc discharge and laser ablation can result in impurities and defects but may be more cost-effective for some applications.

- Alignment and Orientation

The orientation and alignment of multi-walled carbon nanotubes can be influenced by the synthesis method. In the case of CVD, nanotubes are often grown vertically. This is advantageous for applications like field emission displays. Other methods may yield randomly oriented or tangled nanotubes.

- Length and Aspect Ratio

The length of multi-walled carbon nanotubes can vary depending on the synthesis method. CVD processes can generate longer nanotubes, which is desirable for reinforcing composite materials. Shorter MWCNTs may be produced using other methods.

- Functionalization and Surface Chemistry

Some synthesis methods may result in nanotubes with specific surface chemistry. This can impact their compatibility with other materials and their reactivity in various applications. Functionalization techniques can be used to modify the surface chemistry of MWCNTs when needed.

- Cost and Scalability

The cost and scalability of synthesis methods are important factors. While some methods are efficient for producing small quantities of high-quality MWCNTs for research purposes e.g. laser ablation, others are better suited for large-scale, cost-effective production e.g. chemical synthesis.

- Environmental Impact

The environmental impact is also a consideration. Some synthesis methods involve the use of hazardous materials or produce harmful byproducts. Researchers are working on greener methods to mitigate this impact.

Applications of Multi-Walled Carbon Nanotubes

Multi-walled carbon nanotubes find applications in a wide range of fields, thanks to their exceptional properties. Let’s look at the common applications of these nanotubes:

- Composite materials

Multi-walled carbon nanotubes are often used as reinforcing agents in composite materials. These nanostructures are added to polymers, ceramics, and metals to create lightweight yet strong materials. This makes them a go-to choice for enhancing everything from aircraft components to sports equipment.

- Energy storage

In the world of energy, multi walled carbon nanotube sheets play a significant role. They’re typically used in supercapacitors and lithium-ion batteries to give these energy storage devices a boost in capacity and performance. The high surface area and conductivity of the nanotubes contribute to better energy storage solutions.

- Nanoelectronics

Nanoelectronics manufacturers use multi-walled carbon nanotubes in the production of transistors, interconnects, and sensors. Their electrical properties make them suitable for making conductive and semiconductive parts in electronic devices.

- Sensors

Multi-walled carbon nanotubes boast a high surface area and excellent electrical conductivity. This is one of the reasons they are preferred for the production of highly sensitive sensors. You’ll find them in gas sensors, biosensors, and chemical sensors, where they pick up on changes in electrical resistance when exposed to different substances or environmental conditions.

- Thermal management

When it comes to thermal conductivity, multi-walled carbon nanotubes shine. This is why they are used in thermal management solutions. They aid in heat dissipation in electronic devices and even in advanced cooling systems.

- Drug delivery

These carbon nanotubes also play a significant role in the field of medicine. Their structure allows for the transportation of therapeutic agents to specific targets within the body. They are known to potentially improve the effectiveness of medical treatments.

- Water purification

Multi-walled carbon nanotubes also find applications in water purification technologies. They are used to remove pollutants and contaminants from water sources. Some of the properties that make the carbon nanotubes useful in purifying and filtering water include high surface area and adsorption capacity.

- Aerospace and aerospace materials

The aerospace industry benefits from multi-walled carbon nanotubes due to their lightweight yet robust nature. They can be integrated into aircraft materials to reduce weight, which is critical for fuel efficiency and overall performance.

- Biomedical applications

Multi-walled carbon nanotubes are used in various biomedical applications, including tissue engineering, biosensors, and imaging technologies. They offer promising solutions in the field of healthcare and biotechnology.

As you can see, multi walled carbon nanotubes are incredibly versatile and have the potential to shape the future of materials science, energy, electronics, and healthcare.

The Future Prospects and Potential Developments in the Use of MWCNTs

The future prospects for multi-walled carbon nanotubes are both exciting and promising, especially with technological advancements. Let’s look at some potential developments and applications that hold great potential:

- Advanced Materials

Multi-walled carbon nanotubes are already being used to reinforce composite materials. In the future, we can expect to see even more innovative applications in aerospace, automotive, and construction industries.

- Electronics and Sensors

MWCNTs are candidates for the development of high-performance electronic components, such as transistors and sensors. Their integration into smaller, more efficient electronic devices is a promising area of development.

- Energy Storage

These nanotubes show promise in improving the efficiency of energy storage devices, such as batteries and supercapacitors.

- Nanocomposites

The development of MWCNT-based nanocomposites is a burgeoning field. These nanocomposites can offer a combination of unique properties that would allow for tailored solutions in various industries, including aerospace, automotive, and construction.

- Biotechnology and Biomedical Devices

Multi-walled carbon nanotubes have the potential to advance biotechnology by enabling innovative diagnostic tools and improved tissue engineering techniques.

- Environmental Monitoring

Multi walled carbon nanotube sheet can be utilized in sensors for monitoring air and water quality. This could help us better understand and address environmental challenges.

While the prospects for multi-walled carbon nanotubes are indeed bright, it’s essential to continue addressing safety concerns and responsible manufacturing practices as these applications expand. The ongoing research and development in the field are likely to unlock even more exciting possibilities.

Challenges and Safety Concerns in the Production and Application MWCNTs

The production and application of MWCNTs come with their own set of challenges. One major hurdle is achieving consistent quality and properties in the mass production of multi-walled carbon nanotubes.

These nanotubes have intricate structures, and variations in their dimensions and characteristics can affect their performance in different applications. Researchers and manufacturers are working tirelessly to establish reliable and scalable synthesis methods while maintaining consistent quality control.

Another challenge lies in dispersing MWCNTs effectively. Due to their high aspect ratio and strong van der Waals forces, they tend to agglomerate, making it challenging to uniformly distribute them in various matrices, such as polymers or liquids. It’s important to achieve proper dispersion in order to harness their full potential in composites and other applications.

Safety Concerns and Toxicity

Multi-walled carbon nanotubes, when inhaled or introduced into the body, can lead to health issues, including lung inflammation, damage, and a potential risk of cancer. It’s important to implement stringent safety protocols when handling MWCNTs.

Environmental safety is another concern. Improper disposal of MWCNT-containing products can lead to their accumulation in ecosystems, potentially harming aquatic life and other organisms. It is essential to develop recycling and waste management strategies to prevent ecological damage.

Strategies and Research on Mitigating Issues

To address these challenges and safety concerns, ongoing research and strategies are in place. Scientists are actively investigating the toxicity of MWCNTs and understanding the mechanisms of their interactions with living organisms. This knowledge helps in developing safety guidelines and recommendations for handling and exposure limits.

Efforts are also underway to standardize testing methods and regulations specific to MWCNTs. This will facilitate better assessment of their safety and enable more effective control over their production and use.

In terms of production, safer and more sustainable manufacturing processes are being developed to minimize environmental impacts. This includes exploring green synthesis methods and reducing the use of harmful chemicals in the production of MWCNTs.

To mitigate the dispersion challenge, researchers are developing innovative techniques such as functionalization. This modifies the surface properties of MWCNTs, making them more compatible with different materials and enhancing their dispersion.

Conclusion

Multi-walled carbon nanotubes hold immense potential in various fields. Their versatility and applications in advanced materials, electronics, energy storage, and biotechnology are transforming technology and innovation. However, safety and sustainability must remain paramount.

Continued research, stringent regulations, and responsible usage are vital. Let’s harness the potential of multi-walled carbon nanotubes while ensuring the well-being of our environment and health.

Frequently Asked Questions

- What are Multi-Walled Carbon Nanotubes?

Multi-walled carbon nanotubes are cylindrical nanostructures composed of multiple concentric layers of graphene sheets. They are a type of carbon nanotube with a unique structure.

- What are the key properties of MWCNTs?

MWCNTs are known for their exceptional mechanical strength, high electrical and thermal conductivity, and large surface area, making them versatile for various applications.

- How are MWCNTs synthesized?

Multi-walled carbon nanotubes can be synthesized using methods like chemical vapor deposition (CVD), arc discharge, laser ablation, and chemical reduction of oxides.

- Are MWCNTs toxic to humans?

Inhalation of airborne MWCNTs may pose health risks, similar to asbestos fibers. Research on their toxicity is ongoing to ensure safe handling.

- What is the role of catalysts in MWCNT synthesis?

Catalysts are crucial in methods like CVD, as they provide sites for carbon atoms to grow into nanotube structures.