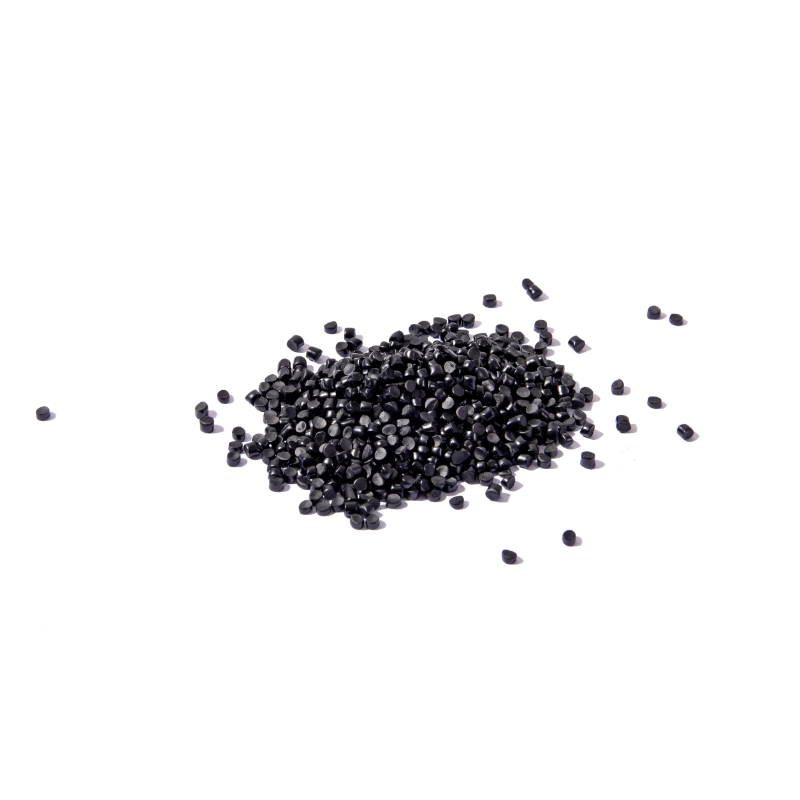

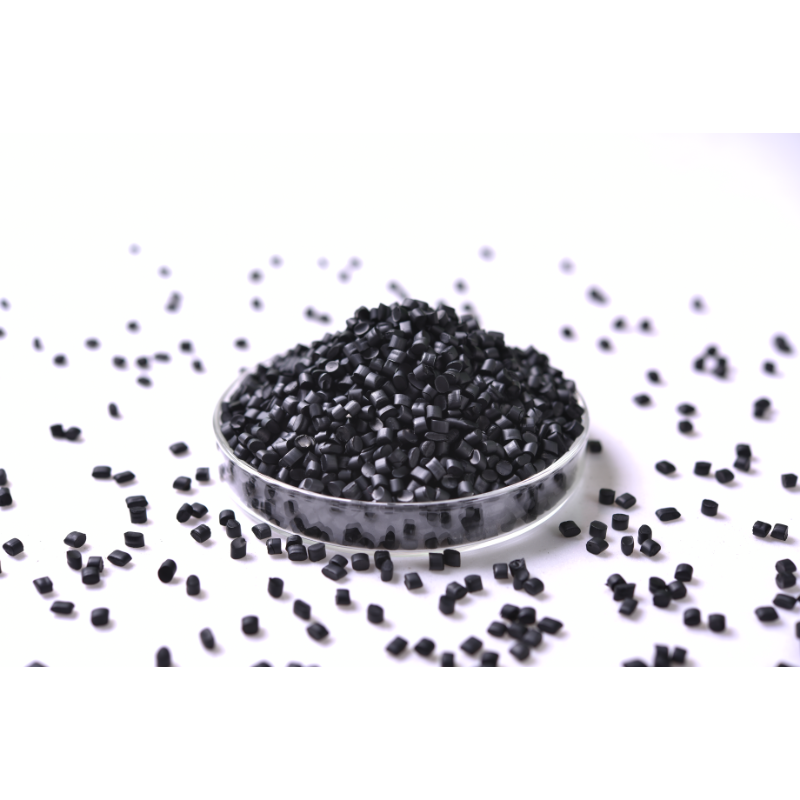

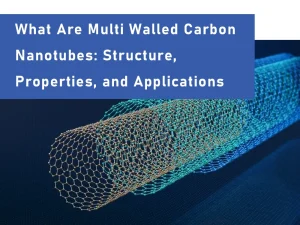

Your Reliable Multi-walled Carbon Nanotube Composites(DZPLAS) Manufacturer

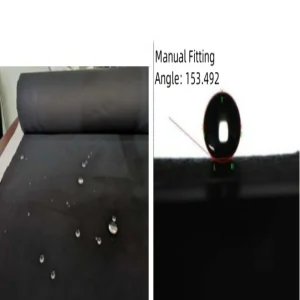

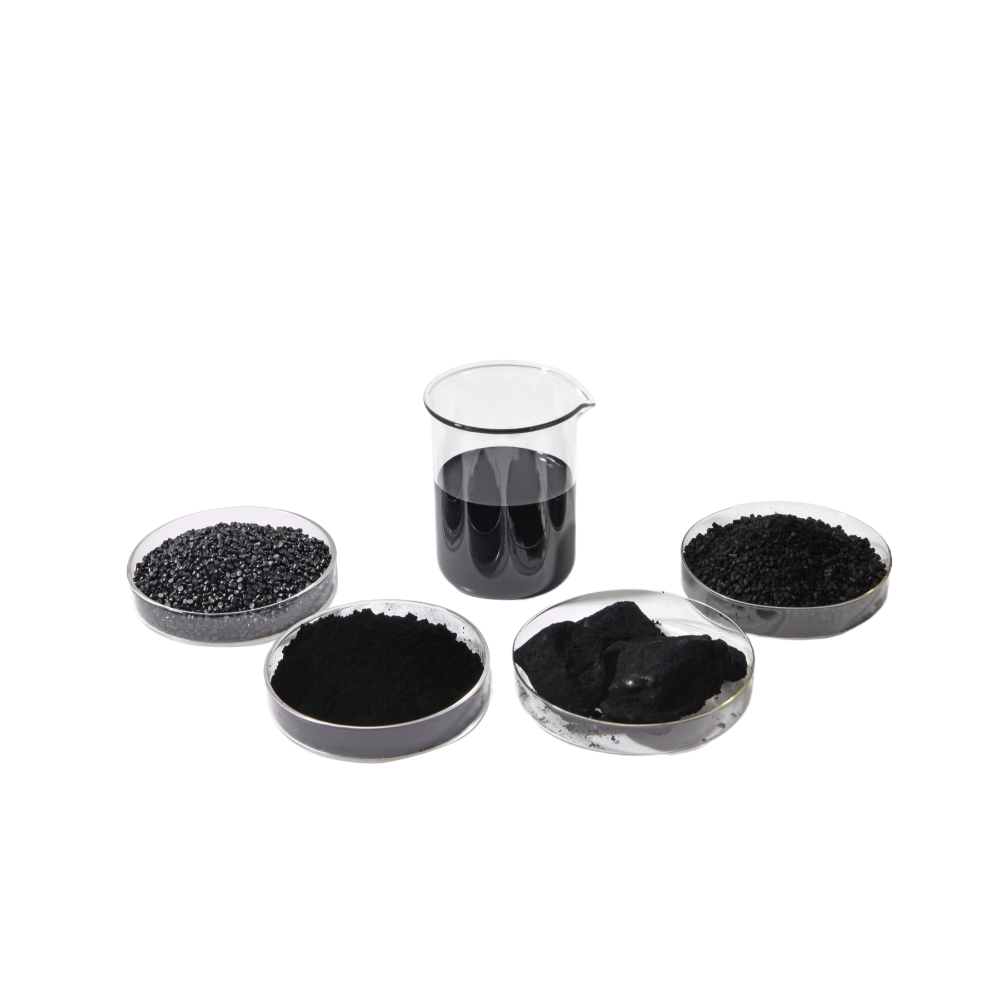

Dazhan Carbon Nanotube Composites, DZPLAS, is designed for conductivity and strength applications. These CNT thermoplastic concentrates improve cleanliness, thermal dissipation, and recyclability. They also protect against flame, give a rich ebony tint, and shield against ultraviolet rays.

These concentrates typically contain 10% to 20% of carbon nanotubes.

Carbon Nanotube Composites are available in various thermoplastic resins, including PC, PP, PA, HDPE, ABS, PA6, HIPS, etc.

We offer quantities of Carbon Nanotube Composites from 20 or 25-kg bags or boxes to containers holding tons.

Carbon Nanotube Composites is recommended for applications requiring a surface resistivity from 1 Ω to 1012 Ω. Typical loading for static dissipative applications is around 2% to 3% of carbon nanotubes in the final compound.

Send Inquiry

- Base: plastic matrix

- CNT loading: 10-20%

- MOQ:1kg

- Lead time: promote

Please get in touch with us to get industrial multi-walled carbon nanotube thermoplastic masterbatch prices and samples.