In the realm of lithium-ion batteries, carbon nanotubes (CNTs) have emerged as a revolutionary conductive agent, setting a new standard for efficiency and performance. These nanomaterials are not just an alternative to traditional conductive carbon black, graphite, and carbon fibers but are a significant upgrade due to their exceptional properties such as a high aspect ratio, vast specific surface area, and notably low volumetric resistivity. By incorporating just 0.5-1% of CNTs into various electrode materials, manufacturers can achieve superior conductivity and battery performance.

The Superiority of Carbon Nanotubes in Conductivity

Carbon nanotubes excel in forming conductive networks on the surface of active materials, enhancing the binding strength between the active material and the current collector, and reducing the amount of conductive agent needed. When used as a negative electrode conductive agent, CNTs exhibit a certain capacity for lithium insertion, synergizing with the anode material to boost the specific capacity of the composite electrode.

Optimizing Conductive Agent Usage: The Percolation Threshold Theory

The addition of conductive agents follows the “percolation threshold” theory, which posits that beyond a certain point, adding more conductive agent does not significantly improve the conductivity of the electrode material. While traditional carbon black conductive agents are typically added at 3%, the efficient conductivity of CNTs allows for a reduction in the amount used to 0.5-1.0%.

Evaluating the Quality of Conductive Pastes

The quality of conductive pastes is critical, and several tests are employed to assess their properties:

-

Solid Content:

The percentage of the residue of the carbon nanotube conductive paste after drying under specified conditions to the mass of the paste before drying. Note: The solid components of the paste after drying include carbon nanotubes and possibly existing dispersants, stabilizers, etc.

Simple measurement method: Take a small amount of paste, mass W, spread it into a thin film in a container, dry the solvent at a certain temperature, then weigh the mass w, and the solid content N=w/W.

-

Fineness: The size of CNT agglomerates in the paste, with instruments like a scraper fineness meter, laser particle size analyzer, or nano particle size distribution instrument used for measurement.

The size of the carbon nanotube agglomerates in the paste.

Currently, the fineness can be measured using a scraper fineness meter, a laser particle size analyzer, or a nano particle size distribution instrument. In the industry, the fineness is often used to detect the dispersion degree of particulate materials in the paste. Fineness is an important performance indicator of battery paste, which has a great impact on the surface quality, uniformity of the formed coating, and the storage stability of the paste. Paste with fine particles and good dispersion, its solid particles can be well wetted, the prepared coating is uniform, the surface is smooth, there will be no vertical scratches, and during storage, particles are not prone to sedimentation, caking, and other phenomena, indicating good storage stability.

-

Volume Resistivity: The resistance per unit volume of the film produced from the CNT paste.

The resistance per unit volume of the film made from the carbon nanotube paste.

Test method: Take an appropriate amount of paste sample and place it on a PET film, use a 200-micron applicator to coat, dry, cut, compact, and test the volumetric resistivity with a four-probe resistivity meter. The distribution state of the conductive agent in the paste is quantitatively analyzed through resistivity, thereby judging the dispersion effect of the paste. If further evaluation is needed, it should be mixed with active material, binder to make a pole piece, to evaluate the coating and conductivity of the conductive paste.

-

Viscosity: The internal friction within a fluid, which for lithium battery pastes, decreases with increasing shear rate.

Viscosity, also known as viscosity or internal friction, is a characteristic of a fluid that hinders its relative flow, that is, the property of a liquid material under stress during deformation, which depends on the rate of deformation. A rotational viscometer can be used to characterize this indicator.

Lithium battery paste is a shear-thinning non-Newtonian fluid, whose viscosity decreases with the increase of shear rate. Therefore, the viscosity of the paste should be defined under the condition of shear rate.

-

Moisture Content: The proportion of water in non-aqueous CNT pastes, critical for the preparation of lithium battery pastes.

The proportion of moisture in non-aqueous system carbon nanotube paste.

Currently, the Karl Fischer-Coulomb method is basically used to determine the amount of water in oily paste. It has a huge impact on the preparation of lithium battery paste. PVDF will generate gel-like substances when encountering excessive moisture, causing poor flow and leveling of the paste, which is not conducive to the coating of the paste. In addition, excessive moisture can cause the decomposition of the electrolyte, producing hydrofluoric acid, which is a particularly corrosive acid, causing serious damage to the positive and negative electrode materials of the lithium battery and the current collector, ultimately leading to safety issues with the battery. Moreover, in different material systems, the moisture content has a great impact on the performance of the battery. However, what is constant is that moisture affects the initial charge and discharge capacity, internal resistance, battery cycle life, and battery volume of the lithium battery.

-

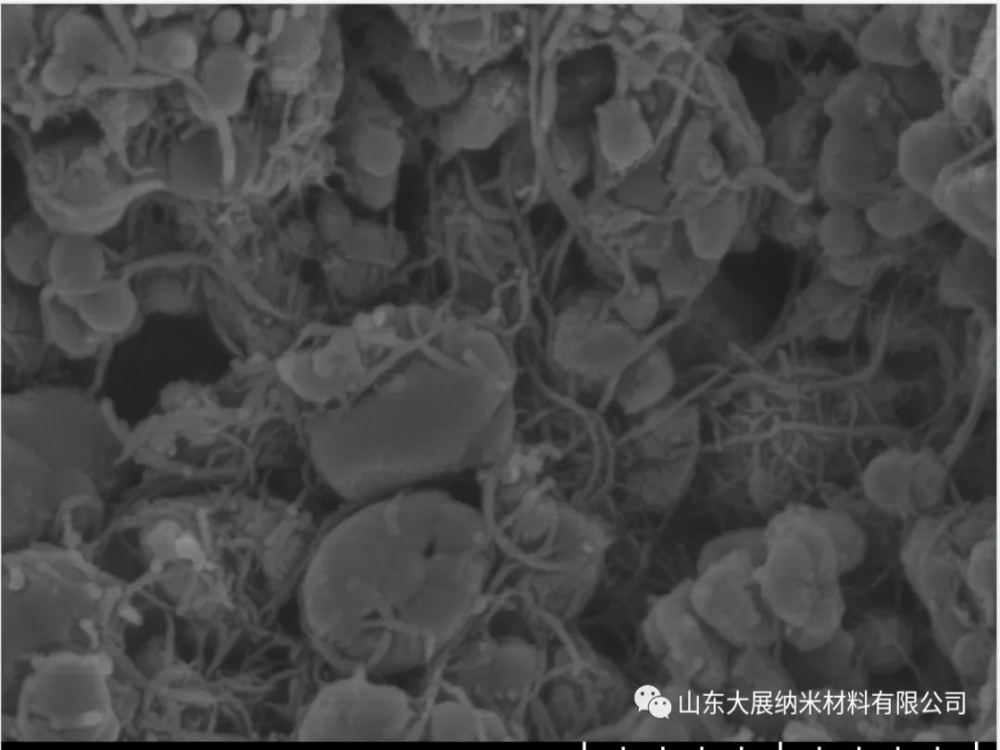

Morphology and Distribution: SEM/EDS/cryogenic electron microscopy techniques are used to observe the paste morphology and the dispersion of components.

Scanning electron microscopy can directly observe the morphology of the paste, combined with energy spectrum analysis to analyze the dispersion of each component. However, during the sample preparation process, the paste may redistribute itself when drying, while cryogenic electron microscopy can maintain the original distribution state of the paste and has also begun to be applied to the analysis of paste properties.

-

Metal Content: The proportion of metal substances in the conductive paste.

The proportion of metal substances in the conductive paste.

Generally, ICP or AAS is used to detect that the total content of magnetic foreign matter (Fe, Cr, Ni, Zn, Co) in the paste does not exceed 0.002% of the carbon tube content (mass fraction). The content of soluble metal impurities (Fe, Cr, Ni, Cu, Zn, Co) does not exceed 0.2% of the carbon tube content (mass fraction). If the user has special requirements, it can be determined through negotiation between the supplier and the buyer.

-

ZETA Potential: A measure of the dispersion and stability of colloids within the paste.

ZETA potential is the potential at the shear plane, also called electrophoretic potential or ζ-potential, which is an important indicator of the dispersibility and stability of colloids, measuring the strength of the repulsive or attractive forces between particles.

The smaller the molecule or dispersed particle, the higher the absolute value of the Zeta potential, the more stable the system.

The Impact of Carbon Nanotubes on Lithium-Ion Batteries

The incorporation of carbon nanotubes into lithium-ion batteries is not just an enhancement; it’s a transformative shift in the way we approach energy storage. With their high conductivity and structural benefits, CNTs are paving the way for more efficient, durable, and powerful batteries that could redefine the landscape of portable power.

Meta Keywords: Carbon Nanotubes, Conductive Agent, Lithium-Ion Batteries, Energy Storage, Electrode Materials, Battery Performance, Conductivity, Percolation Threshold, CNT Paste, Volume Resistivity, Viscosity, Moisture Content, SEM Analysis, ZETA Potential

Meta Description: Discover how carbon nanotubes revolutionize lithium-ion batteries with superior conductivity and performance, reducing conductive agent usage while enhancing efficiency.