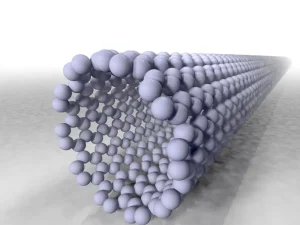

Development in science and technology was made possible by carbon nanotubes (CNTs). They can conduct heat and electricity and offer resistance. They also might not be able to bear a load or conduct electricity. If they are to accomplish anything good, they must be arranged. Unordered CNTs have low efficiency when compared to ordered CNTs. Structuring them gives strength and enhances their conductivity. It is quite challenging due to its diminutive size and inclination to agglomerate. Sensors would be rendered functionless due to misalignment and clustering. How to arrange carbon nanotubes? This article will discuss arranging carbon nanotubes, applications, and prospects.

How to Arrange Carbon Nanotubes: A Key Techniques

Layer-by-Layer Assembly

Layer-by-layer assembly can form high-precision multilayered CNT architectures. The Langmuir-Blodgett technique on liquid surfaces pushes CNT layers together. These are first deposited onto solid surfaces. Charged CNTs and polymers are built up by electrostatic deposition in alternate layers. This method forms ordered structures. The method offers good alignment and thickness control. This features makes optoelectronics and sensors the best. Still, the process is slow and painstaking. Despite these constraints, it is unmatched in precision. It is a perfect choice for high-end CNT devices.

Mechanical Techniques

Physical forces align carbon nanotubes (CNTs) through mechanical processes. Composite CNT nanotubes result from tension. Permanent alignment of CNTs occurs due to shear stresses. It includes due to extrusion or spin coating. Factory roll-to-roll processing elongates films to orient CNTs. These technologies support existing manufacturing methods. This makes them suitable for manufacturing with embedded CNTs. However, this is not as precise a process as others. Also, degrading CNTs and reducing their performance is undue tension. This restricts their fit in some instances. These processes are handy but must be achieved with the necessary precautions.

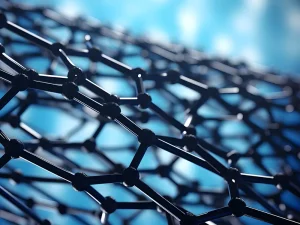

Self-assembly

CNTs do the self-assembly very readily. Quite naturally, the forces are being imposed to order the CNT to be placed in a particular way. Surfactants and solvents disperse CNTs in an orderly fashion. This makes the particles not aggregate or else add very slightly. The surface modifications made to the CNTs allow them to interact directly with some materials. Peptide is in charge of the construction of the structures to encapsulate CNTs. Its costs would be low and an ideal method to deal with enormous usage demands. Nevertheless, it is not easy to achieve the best results. The process is effective if the procedure of preparing is carefully undertaken.

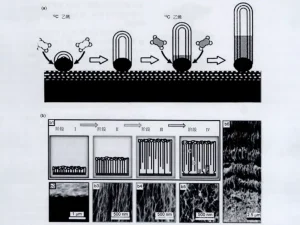

Chemical Vapor Deposition (CVD)

Chemical vapor deposition (CVD) is a popular technique for the surface growth of carbon nanotubes. Metals like nickel or iron are first deposited on a substrate as a catalyst. The process starts to grow CNTs by pumping high-temperature carbon-rich gasses. The modification of the gas flow in the chamber can lead to forests of CNTs being grown vertically. CVD-electronic applications purify and align CNTs to very high standards, resulting in high purity of CNTs. However, the CVD method uses specialized equipment and requires precise parameter settings. This method is costly and has a low scalability rate, weighing in both its complexity and expense.

External Field Alignment

Extrinsic fields are needed to allow CNT alignment. Dielectrophoresis is applied in electric fields to move the polarized CNTs in liquids. The process is fairly easy and allows the CNTs to be embedded into flexible electronics. When magnetic fields are applied, the iron oxide nanoparticles are aligned on the functionalized CNTs. The particles’ density and direction are controlled by varying the field’s strength. The approach is universal and can be used for any application.

However, the use of magnetic particles in CNTs changes their auto-properties. It is beyond comprehension to achieve uniform orientation for vast coating spaces. A certain degree of these parameters needs to be controlled, and it is not easy in large quantities. On the other hand, there is a good way to build CNTs on a small scale.

Applications of Arranged CNTs

Composites

Structuring carbon nanotubes (CNTs) is revolutionizing composite materials. They enhance polymers, metals, and ceramics with strength and hardness. Aligned CNTs enhance weight-stiffness capacity by distributing strain evenly. The products also come in handy for sports gear such as tennis rackets and bicycles. Nevertheless, bulk production of CNT composites is challenging. The challenges come in the form of cost and the requirement of steady supplies. These issues must be addressed so that improved utilization can ensue.

Electronics

Aligned carbon nanotubes (CNTs) are transforming the electronics industry. They act as fast transistors and wire in microchips. Performance is improved this way. Directional conductivity increases signal transfer for flexible touch screens and wearables. Aligned CNT arrays help create lower-energy components and smaller components. For instance, transistors made of CNTs surpass silicon-based transistors under some conditions. Alignment is fundamental to achieving high uses of CNTs for electronics. However, the incorporation of aligned CNTs into current manufacturing is still challenging. This is a significant hurdle for broad applications.

Biomedical Devices

Aligned carbon nanotubes (CNTs) are opening up new vistas in biomedicine. CNTs act as scaffolds for tissue engineering by adhering to the geometry of natural tissue. Particular biomarkers could be detected using aligned CNT-based biosensors. Aligned CNT-based neural interfaces are found to be efficient in conveying electric impulses. The best functioning of these technologies requires that they be in harmony. However, there are issues with their physical health. Also, long-term consequences must be analyzed. These problems have to be addressed before their use.

Challenges in CNT Arrangement

Organizing carbon nanotubes (CNTs) is challenging. Moving from lab methods to mass production is costly and slow. Rough handling damages CNTs and hurts their performance. Evenness over large areas requires careful work. Adding aligned CNTs to current tech needs compatibility tests. Scientists must solve problems like regularity and cost. Beating these challenges is key to unlocking CNTs’ potential in many fields.

How to Arrange Carbon Nanotubes: Future Trends

The future of carbon nanotubes depends on new ideas. Biomimetic copies nature to improve alignment. 3D printing can create complex structures layer by layer. Hybrid methods, like mixing CVD and magnetism, could boost precision. Machine learning can find the best alignment settings fast. These advances will push CNT technology forward. Collaboration across fields is key to breaking current limits.

Conclusion

This article explains how to arrange carbon nanotubes to achieve their full potential. Techniques such as CVD and external fields have unique advantages. CNTs are applied in electronics, composites, and energy storage, setting their varied uses. Yet, issues such as scaling up and integrating existing systems must be addressed. New concepts such as biomimetic methods and machine learning have immense potential. By overcoming these constraints, scientists can use CNTs to revolutionize industries.