Understanding the unique properties of carbon-based materials is crucial in various scientific and industrial applications. Among these materials, carbon nanotubes (CNTs) stand out due to their remarkable electrical, thermal, and mechanical properties. However, given their similarity in appearance to other carbon-based substances, effective characterization techniques are essential. This guide delves into the most common methods used for the characterization of carbon nanotubes.

Scanning Electron Microscopy (SEM) for CNT Analysis

SEM is a primary tool in the characterization of carbon nanotubes. It provides detailed images of CNTs, allowing for the analysis of their morphology and distribution. By coating the nanotubes with a thin layer of gold, SEM can reveal the intricacies of CNT structures at high magnifications, essential for assessing their quality and uniformity in composites.

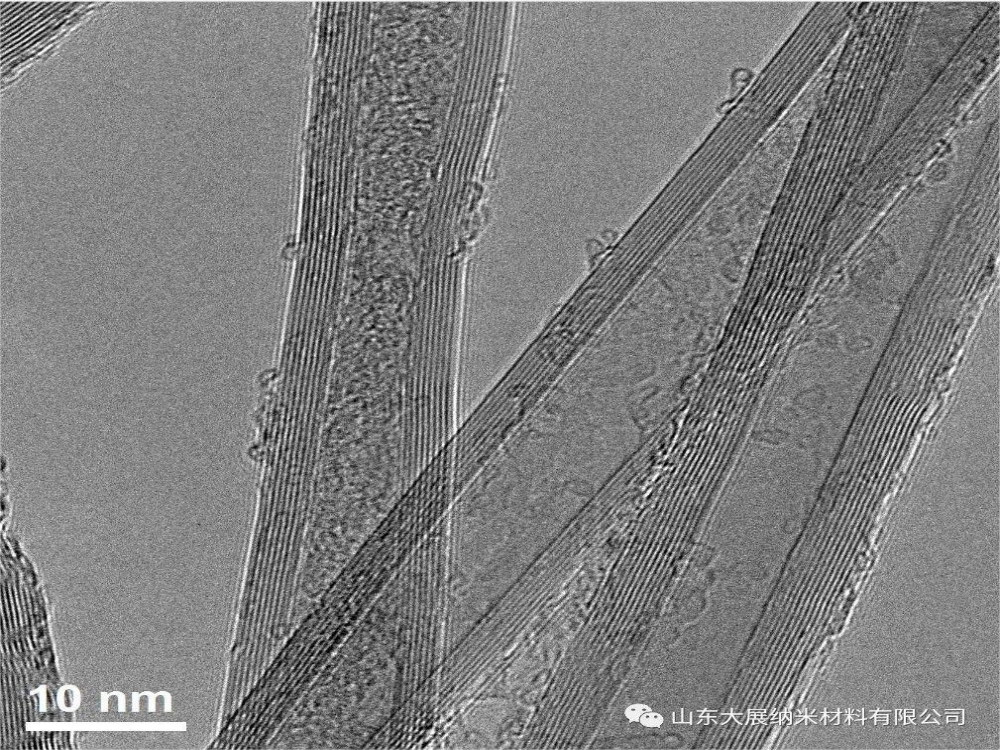

Transmission Electron Microscopy (TEM): A Closer Look at CNTs

TEM is another pivotal technique in the characterization of carbon nanotubes. It offers a cross-sectional view, enabling precise measurements of CNT diameters and the determination of wall numbers. This method is particularly useful for assessing the structural integrity and purity of CNTs.

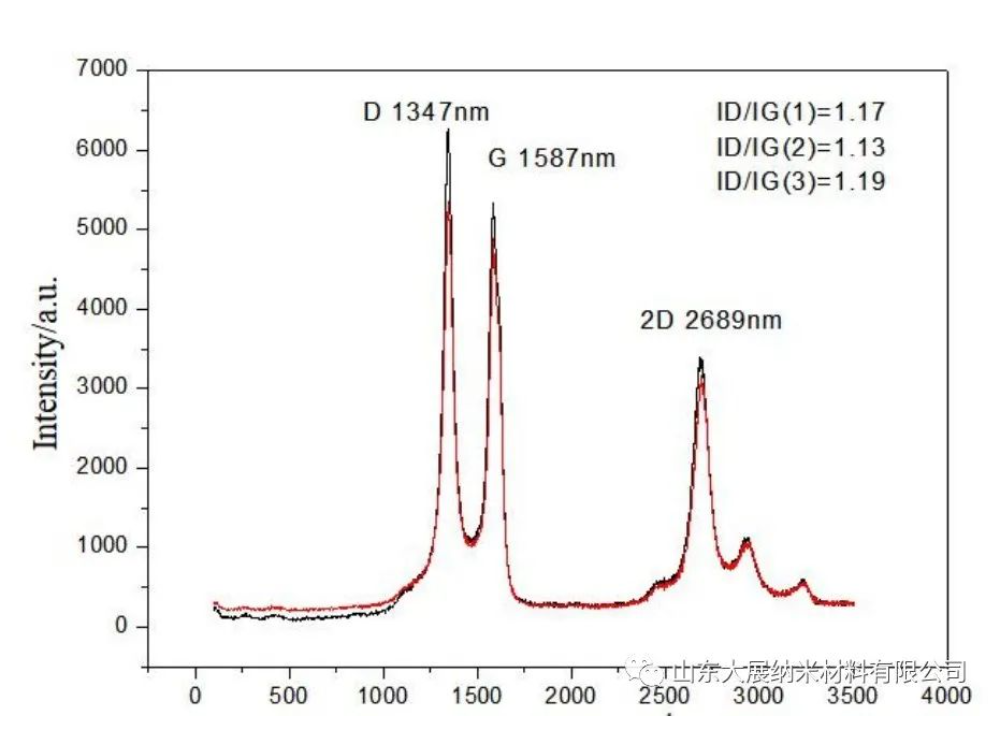

Raman Spectroscopy: Deciphering CNT Quality

Raman spectroscopy provides insight into the defect levels and graphitization of carbon nanotubes. The D and G peaks in the Raman spectrum serve as indicators of CNT quality, with the IG/ID ratio being a commonly used metric for evaluating their crystallinity.

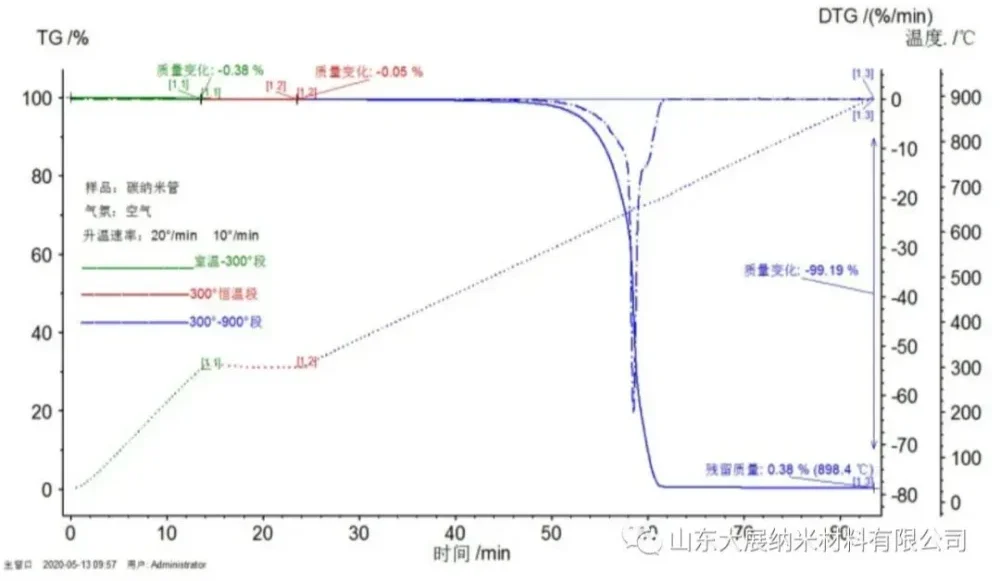

Thermogravimetric Analysis (TGA) for CNT Stability

TGA is a technique used to assess the thermal stability and compositional purity of carbon nanotubes. By monitoring weight changes at controlled temperatures, TGA can provide valuable information on the thermal degradation of CNTs, which is crucial for their application in high-temperature environments.

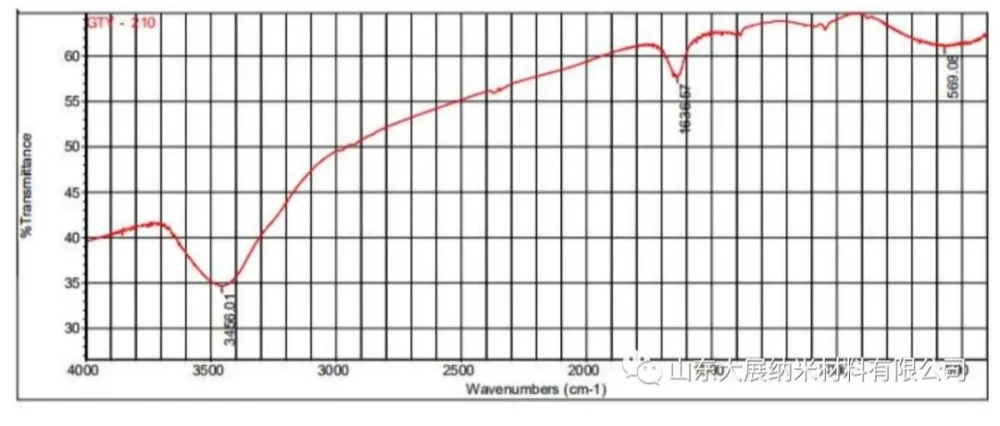

Infrared Spectroscopy (IR): Identifying Functional Groups on CNTs

IR spectroscopy is employed to identify the types of functional groups present on the surface of carbon nanotubes. This characterization is vital for understanding the surface chemistry of CNTs, which affects their interaction with other materials.

Four-Point Probe Resistivity Measurement for CNT Conductivity

The electrical conductivity of carbon nanotubes is a defining characteristic. The four-point probe method is used to measure the resistivity of CNT powders and composites, providing a quantitative evaluation of their conductive properties.

Surface Area Analysis: Assessing CNT Interaction Potential

The specific surface area of carbon nanotubes is indicative of their interaction potential with other materials. Surface area analyzers measure this property by evaluating the adsorption of gas molecules on the CNT surface, which is particularly relevant for applications in catalysis and energy storage.

Conclusion: Pioneering CNT Applications with Dazhan Nanomaterials

At Dazhan Nanomaterials, we are at the forefront of integrating carbon nanotubes into commercial applications, particularly in the field of lithium-ion batteries. As a leading supplier, we offer a diverse range of CNT products, ensuring that our clients have access to the highest quality materials for their needs. Our commitment to the development of carbon nanotube technology is unwavering, as we continue to explore the vast potential of these materials for future innovations.