Equipment Standard Specifications

1. Introduction to the main equipment

This equipment is specially designed for carbon nanotube slurry and graphene conductive slurry. It has a large screen filtration area, pipeline cooling, and an aluminum alloy jacket outside the grinding chamber. It ensures that the cooling water and the grinding chamber are completely isolated, and there is no metal exposed in the grinding chamber, which can achieve continuous grinding and dispersion of ultra- high viscosity materials.

2. Name and specification of main equipment

Product name: All-ceramic turbine nano sand mill Model: MNW90L

Design volume: 90L

Applicable viscosity of the product: 0-80000CPS

Main motor power: 90KW

Overall dimensions: 2000mm×1750mm×2100mm

Machine weight: 4.8 tons (excluding grinding beads)

3. Configuration of the main equipment

| Serial Number | Name | Specifications | Unit | Quantity | Remark |

|---|---|---|---|---|---|

| 1 | All-ceramic Turbine Nano Sandmil | MNW90L | Tower | 1 | Standard |

| 2 | Pneumatic Diaphragm Pump | 1.5 inch | Tower | 1 | Standard |

4. Equipment water, electricity and gas requirements (single equipment)

A. Power demand

B.Power system: TN-S system (commonly known as three-phase five-wire system);

C. Power supply voltage: AC380V 50Hz

D. Control voltage: DC24V

E. Cold water demand

F. Water supply pressure: 0.05MPA-0.3 Mpa Cold water flow: 25m3/h

G. Cold water temperature range: 8-15℃

H. Ph value: 6.9~7.2 (neutral)

I. Air compressor: 7m3/min, air supply pressure: 0.4~0.72 Mpa

Main Structure And Description Of The Equipment

1. Frame

The main machine consists of a base, a shield, a bearing seat, a motor bracket and other components. The bearing seat is made of ductile iron, and the others are Q235.

2. Mechanical seal

It is produced by a professional mechanical seal manufacturer (imitating Germany’s Borgmann), with double-end mechanical seals. The sealing ring is made of perfluoroether, a wear-resistant and corrosion-resistant material, the dynamic ring is made of high-quality alloy, and the static ring is made of silicon carbide. It has a forced sealing liquid circulation cooling system. The sealing liquid can be selected according to the customer’s requirements. The solution that does not affect the quality of the material is kept under pressure by clean compressed air.

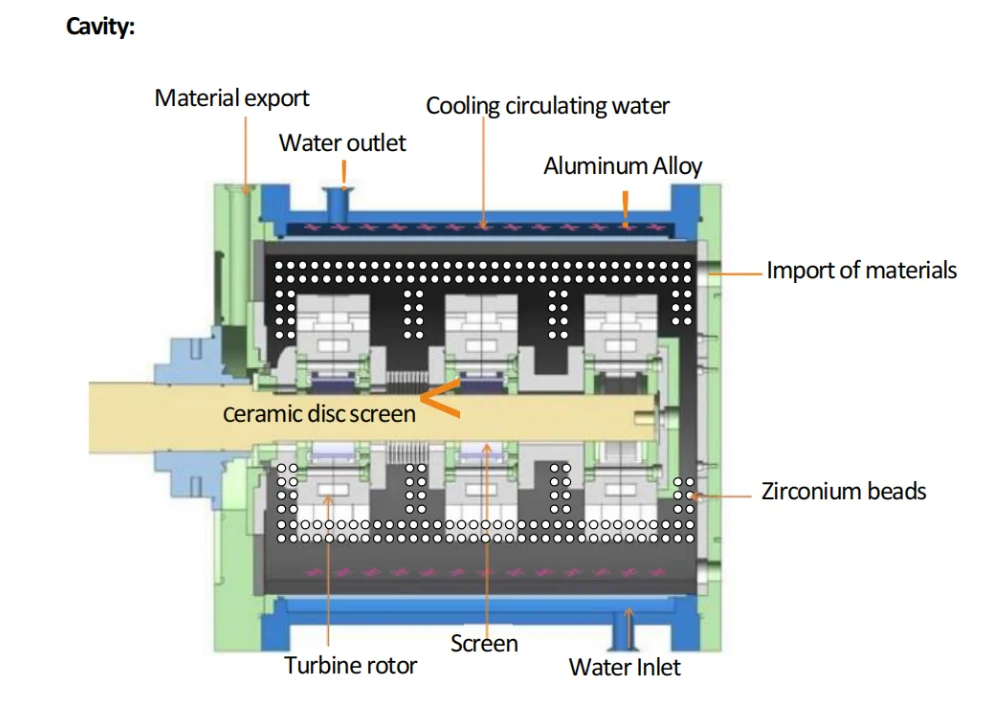

3. Grinding chamber

The cylinder adopts a silicon carbide-inlaid aluminum alloy structure (the outside of the aluminum alloy is a stainless steel barrel, and the middle is a cooling water circulation channel). The two end faces are sealed with double channels to ensure that the cooling water and the material are completely isolated, and at the sametime, the strength of silicon carbide is increased.

4. Motor drive and motor control

Adopt Wannan explosion-proof motor, explosion-proof structure DIIBT4, protection level Ip55, 3-level energy consumption, the motor adopts Anbangxin inverter, high control accuracy, energy saving and environmental protection.

5. Inlet and outlet pump

1.5-inch pneumatic diaphragm pump, Teflon diaphragm.

Air consumption: 0.9m3/min, material flow 0~15m3/h.

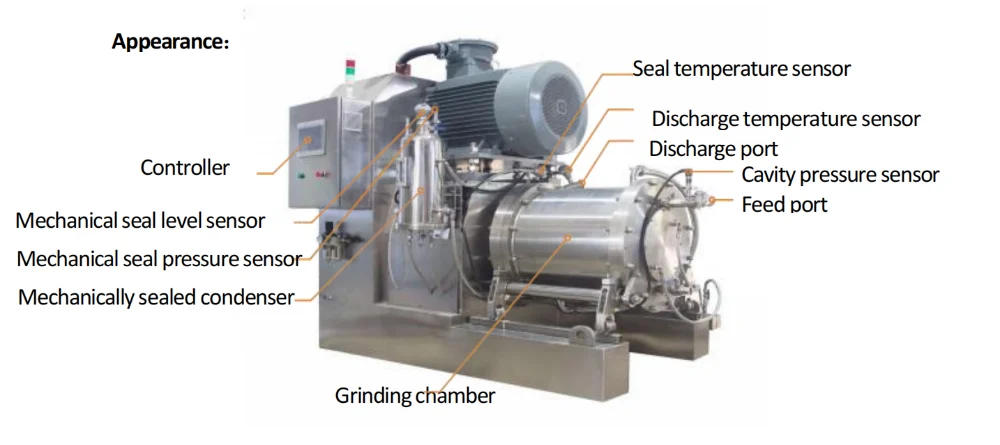

6. Temperature and pressure protection

Guangzhou Jingbei precision temperature sensor PT100, measurement range 0~100℃, automatic shutdown protection when the material temperature exceeds the set upper limit. Precision pressure transmitter, measurement range 0~1.0Mpa, Automatic shutdown protection when the pressure in the grinding chamber is higher than the set value.

7. Interactive human-machine interface:

A. Real-time display of discharge temperature

B. Real-time display of chamber pressure

C. Current operation time

D. Real-time display of spindle speed

E. Total operation time of grinder

F. Real-time display of machine seal temperature

G. Real-time display of machine seal pressure

H. Real-time monitoring of safety alarms (machine seal failure, over-limit of bin temperature and pressure, etc.)

8. All sealing materials that may come into contact with solvents are imported fluororubber, perfluoroether, tetrafluoroethylene, etc.

9. The transmission bearing brandis SKF imported from Switzerland.

10. The equipment adopts a stainless steel exterior, a parallel structure, and a shock-absorbing pad support, which is directly placed on the horizontal ground. The ground bearing pressure is 750kg/㎡, ensuring that the equipment is stable and will not shake during operation.

Equipment Appearance And Grinding Chamber Structure

Features of MN-W90L Carbon Tube Slurry Special Sand Mill

1. Three sets of ceramic turbine dispersion discs are used, with a large discharge area, not easy to be blocked, good dispersion consistency, large dispersion disc diameter and higher efficiency.

2. Grease lubrication is used to prevent oil leakage. A large gap is left between the machine seal and the bearing, and a PTFE pad is added for protection to ensure that the machine seal fluid does not contact the bearing.

3. An aluminum alloy outer cylinder is added to the silicon carbide inner cylinder, and an interference fit is used between the two. The strength of silicon carbide is increased, it is not easy to crack, and the thermal conductivity is much better than the gap fit.

4. Two sealing rings are used to seal the aluminum alloy outer cylinder and the cooling water to ensure that the cooling water and silicon carbide are completely isolated.

5. There is no metal leakage in the grinding barrel cavity, and the screw head is blocked with a PTFE disc.

6. The main engine seal is installed on the bearing seat, the concentricity is improved, and the failure rate is reduced.

7. Wheels are installed under the receiving hopper, which can be moved freely and convenient for maintenance.

8. The outer cylinder is supported by four independent wheels, and the axle is eliminated, ensuring that the weight of the cylinder is completely borne by the axle, the machine stability is improved, and maintenance is convenient.

9. The main shaft is made of S31083 duplex steel material, which has high strength, small vibration when the machine is working, longer service life of mechanical bearings, and better equipment stability.

10. Using PLC intelligent control, the human-machine interface is friendly, the operation is simple, and the monitoring process parameters are more, and the response is more sensitive in abnormal shutdown.

11. The exterior adopts a fully enclosed stainless steel structure to prevent materials from corroding the equipment during the production process.